Because it usually requires very little effort to collect the data necessary for the calculation of Specific Capacity, it is an extremely useful measurement that can be used to identify declines in well performance, which allows for planning an optimal well rehabilitation schedule. The Specific Capacity of a well is the pumping rate (gpm) (Q) divided by the drawdown in feet (s). Specific Capacity can also be used to provide the design pumping rate or maximum yield for the well and to estimate the transmissivity of the surrounding formations penetrated by the well screens. The following equation is used to calculate Specific Capacity:

SC = Q/s

Note: SC = Specific Capacity (gpm/ft); Q = discharge (gpm); s = drawdown (ft)

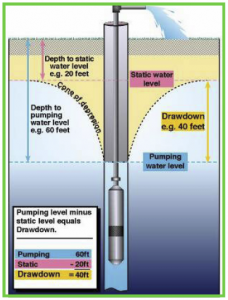

In the figure at the left, the well has a drawdown of 40 feet. If the well was pumping at 200 gpm, the Specific Capacity would be 200 gpm divided by 40 feet of drawdown to give a Specific Capacity of 5.

Typically, a well should run continuously for at least 24 hours at a constant yield before recording the drawdown to allow drawdown to stabilize (Driscoll, 1986). Ideally, to provide the best comparison of Specific Capacity measurements over time and a comparison to the original test results, the same continuous pumping time frame should be used for each subsequent test.

The Specific Capacity obtained just after a well is drilled and properly developed is typically the highest value that will be produced and is the baseline for comparison for all future values. As time goes by, the Specific Capacity will decline as plugging of the well’s perforations or filter pack occurs or as static water levels change. Specific Capacity testing should be performed at least semi-annually and water levels (static and pumping) should be collected monthly to provide early detection of potential well problems. Rehabilitation work should be scheduled when a well’s Specific Capacity drops by 15% or more.

Estimating Maximum Pumping Rate

The maximum pumping rate of a well can be estimated using the initial Specific Capacity. The maximum pumping rate is calculated as the Specific Capacity times the maximum available drawdown. For example, with a well that has 40 feet of drawdown and is pumping 200 gpm has a Specific Capacity of 5. If the well has an available drawdown of 50 feet, the maximum pumping rate would be 5 times 50 feet, or 250 gpm. While this is considered an estimate and more accurate calculations can be developed with a field test, it is a useful approximation for understanding the pumping limits of the well.

Estimating Transmissivity

The initial Specific Capacity value can also be used to estimate the transmissivity (T) of the aquifer. Transmissivity is the rate water is transmitted through an aquifer under a unit width and a unit hydraulic gradient. It equals the aquifer’s hydraulic conductivity (K) times the aquifer thickness (b). The higher the transmissivity, the greater the capability of the aquifer to move water and the lower the drawdown in the well. The following equations can be used to estimate transmissivity per (Driscoll, 1986):

T = 1500 * Q/s (for an unconfined aquifer)

T = 2000 * Q/s (for a confined aquifer)

Note: T = Transmissivity ( gpd/ft); Q/s = Specific Capacity (gpm/ft)

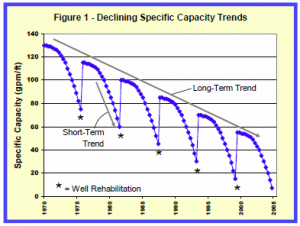

A new well will start to lose Specific Capacity as soon as it starts pumping. The rate of decline will vary from well to well, a good record tracking system will allow declines performance to be tracked so that an optimal schedule for well rehabilitation can be established. The Specific Capacity of the well can be tracked, along with other important measurements, using a series of Key Performance Indicators (KPI) that allow easy recognition of well performance trends through a series of time-series graphs.

A decline in Specific Capacity occurs when the well’s screen, filter pack, or the formation adjacent to the well become plugged from physical processes (sand bridges, silt, and clay particles), chemical processes (mineral incrustations), or biological processes (biofouling). Rehabilitation is performed to remove these blockages and restore the well’s Specific Capacity and improve the well’s efficiency. There are both short-term and long-term declines in Specific Capacity over the normal life span of a well. Short-term declines are caused by the plugging as a result of one or more physical, chemical or biological processes and may be partially reversed with well rehabilitation efforts. However, the causes of the plugging can generally not be removed completely resulting in a chronic, long-term decline in Specific Capacity over the life of the well until Specific Capacity reaches the point where a replacement well is needed (see graph).

Other Factors Affecting Specific Capacity

When turbulent flow occurs in the well, the specific capacity declines as the discharge rate is increased (Sterrett, 2007). It’s important to assess the laminar and turbulent flow components to determine optimal pumping rates and pump depth. This can be accomplished through the use of a step-drawdown test. The relative proportion of laminar and turbulent flow occurring at each step can be derived from the pumping test data using the Jacob model.

There is also evidence that Specific Capacity can be affected by changes in the temperature of the groundwater. This effect is most notable in wells that are located in an aquifer which is directly under the influence of surface water and experiences seasonal temperature changes.

References

Driscoll, F.G., 1986, Groundwater and Wells, Second Edition: Johnson Filtration Systems Inc.

Roscoe Moss Company, 1990, Handbook of Ground Water Development: John Wiley & Sons, Inc.

Sterrett, R.J., 2007, Groundwater and Wells, Third Edition: Johnson Screens

So 200/40=4.9? In my day, that would have been 5, even with a slide rule. Just wondering where the 0.1 went.

Fixed now – I’m not sure how that happened, but thanks for catching my error.

based on the sample well maximum pumping rate of 250gpm what would be my water pump rating? thanks

Specific Capacity is based on the drawdown and pumping rate, with drawdown being the difference between the non-pumping water level and the pumping water level, so if you had a drawdown of 20 feet and were pumping at 250 gallons per minute, your specific capacity would be 250 divided by 20 or 12.5. Just substitute your drawdown for the example and you will come upon with your specific capacity. If you are looking for specifics on your pump efficiency, that is a whole other calculation and we would need a bit more information. If you email me at tballard@sehydrogeology.com, I can give you the specific calculations for wire-to-water pump efficiency.

How do I calculate the available drawdown?

Drawdown is the difference between the static (non-pumping) water level and the water level during pumping. Available drawdown is theoretically the difference between the bottom of the well and the static water level – so, in effect, how much you could pump the water level down before the well goes dry. Typically, we will try to set the pump intake at 70% of available drawdown unless we have pumping test data that indicates we can go shallower.

What is drainable volume for each aquifer in the hydrostratigraphy and how do you calculate it? I do ask this question because the total amount of groundwater to pumped was calculated from the addition of drainable volume quantity plus the recharge. I would like to understand what drainable volume amounts of water mean in an aquifer?

Drainable volumes of water in an aquifer are going to be the specific yield (the value you are looking for), which is essentially equal to the effective porosity. Effective porosity is calculated by the following formula: ((weight of saturated sample – weight of sample after gravity drainage)/(weight of saturated sample – weight of air-dried sample)) x (void volume/total volume) x 100%. This is will give you effective porosity as a percentage of the total volume of rock and that is essentially the same as your specific yield.

What is your opinion of the reliability of using air-lift tests to calculate specific capacity (SC) and estimating transmissivty (T) during well development immediately after drilling? Regulators typically require, as they should, the assumption that the pumping water level is equal to the depth of the air line, but that cannot be determined with this test method. Therefore, SC would be calculated at a lower value, thus affecting the T estimate. Would you assume a high turbulence with this method, thus affecting SC even more?

Are you aware of any research regarding this?

Thanks

Field experience indicates that airlift testing is really only good for order of magnitude estimates of pumping rates and specific capacity. My experience is that airlift tends to overestimate yields in a well, but your experience may vary. What is true is that actual pumping tests and initial airlift results rarely align mand that is mostly because of the turbulence, as well as the fluid properties of air vs water. I think that estimating transmissivity via specific capacity should be used with caution and not be considered as accurate as a pumping test. Even pumping tests are subject to a lot of variables that cannot be controlled, so it is important to understand those results that get calculated to 10 decimal places are not really that precise.

When setting up a spec for an under reamed gravel pack well, what is a good range for the specific capacity? We have a spec that calls out “the minimum specific capacity shall be 20.0 gpm/ft for 1-hour drawdown at 500 gpm or a minimum of 80% well efficiency.” I was thinking that may be a high number.

Specific capacity is really going to depend on a lot on aquifer properties – that is why we do not spec out an actual specific capacity number in the drilling specifications we put together. In some aquifers, a specific capacity of 5 may be as good as you can get because that is all the aquifer will support. Within reason, well efficiency can impact SC, but there are limits based on aquifer properties – mainly transmissivity. You can have a 100% efficient well, but only get 10-20 gpm if you have a really “tight’ aquifer. Well design comes into play, as well. The bottom line is the hydrogeology really comes into play and you cannot specify an SC without knowing your aquifer properties first. I’ve seen some projects that specify that a new well produce a certain gpm – something that is just not realistic in most cases. If I was a driller, I would never sign a contract that required a specific yield. In answer to your question, 20 is a fairly high SC, but not impossible to achieve in the right circumstances. For a 500 gpm pumping rate, that would really translate to 25 feet of drawdown which is certainly realistic if the aquifer will support a 500 gpm pumping rate. I hope that is not an obtuse answer, but I go back to being opposed to to requiring an actual specific capacity number in the drilling specs.

If specific capacity can be estimated as Transmissivity / 1500 for an unconfined aquifer, where does the 15oo come from?

Don’t forget that this method to estimate transmissivity is an approximation. There are a lot of factors that influence transmissivity calculations during a real pumping test, but for most purposes, an approximation is good enough. The specific capacity method provides a quick and dirty method to give a transmissivity without going through the expense and time of a pumping test. That said, the 1500 is essentially a constant based on using typical values in the Jacob straight-line formula, which is itself is a simplified version of the Theis equation. You can find more details on page 1021 of the second edition of Groundwater and Wells by Fletcher Driscoll.

Thomas,

Aquifer test assumptions typically state the aquifer is fully screened or something along those lines.

Question #1

I know there is a correction for unconfined aquifers but is there anything of the sort that needs to be done for highly confined aquifer? In my case the aquifer is screened at 65%, has a T of 132,000 and an estimated efficiency of 31% based on a preliminary constant rate test on the production well and actual and theoretical SC. There are no observation wells involved. That’s not too good of an efficiency.

Question #2

What is your opinion on step rate tests under the above circumstances to evaluate/determine well efficiency? Any supporting references appreciated as I’v seen good and not so good stuff on step test evaluations and have never done them.

Thanks,

Dan

251-510-9355 anytime

Keep in mind that Specific Capacity is most definitely not a pumping test. The primary use of SC is to measure and track well performance over time to determine when a well should be rehabilitated. Getting an approximation of transmissivity is a secondary use of SC and it is not the level of accuracy you would get from an actual pumping test. You are really not going to be able to calculate a well efficiency from just SC. As far as confined vs unconfined, you can estimate transmissivity from SC if you have an idea of what type of aquifer you have, but once again, SC is really a quick and dirty calculation and really trying to tweak the calculation for aquifer types just would not really give meaningful results in my book. I’m assuming when you say “actual and theoretical SC” you actually mean drawdown.

As far as step tests, that is really the best way to calculate well efficiency, especially if you do not have any observation wells. The best reference for all things water well is really Groundwater and Wells, Second Edition, by Fletcher Driscoll. Another reference dfor step tests and well efficiency is a PDF that should be available online: A simple method for calculating well loss by Gholam H. Karami and Paul L. Younger. Of course, when doing pumping test analysis, “simple” is a relative term!

Hi Thomas, I just came across your blog while searching for a schematic of specific capacity to use in my Groundwater Engineering course. I like the schematic you used and wondered if you have, and would mind sharing, a higher resolution version and provide the source to which I will attribute the schematic? Thanks, John

Unfortunately, I do not have a higher resolution version than what you can download directly from the blog. I probably need to draw one up in .svg format to get higher resolution.

how I can calculate a specific drawdown? and is there a difference between specific drawdown and specific capacity?

Generally, they are considered to be the same thing, as I understand it. I don’t really use the term specific drawdown, so others may use it in a different sense.

I’m trying to determine the maximum GPM a well can yield, not based on the pump and available storage but, what the aquifer will allow after the storage is depleted. My pump is flowing at 5.4 GPM at max, it’s not able to pump higher than that. But I’m looking to start irrigating a pasture and would like to install a pump that supports a greater sustainable flow rate such as 15 – 20 GPM if the well can handle it. I did a 24 hour pumping test taking pumping water level measurements every one minute. Before I began the pump test, the water was not used for 24 hours and an initial static water level was 33.99 BGS and after 24 hours of pumping had a total drawdown of 13.2 ft. The recovery portion of the test was extended, 1 hour after pumping stopped the water had risen by 11.25ft, 24 hours later water had risen another 1.32ft and the last measured level was taken 48 hours after pumping had stopped and was measured at 34.2 ft BGS, but still rising very slowly when I stopped measurements. The well depth is 218 ft, with saw slots the bottom 28 ft. up to 190 ft. Radius of the casing is 2 inches with a holding capacity of .65 gallons per foot, from the top of the screen to the bottom of the top confining layer of the aquifer is 105 ft. I have a total saturated thickness of 133 ft. I’m not sure the math or equation I need, the rate is constantly changing for both the drawdown and recovery from fast to slow to slower. I’m trying to determine at what rate water is flowing into the well from the aquifer so I don’t exceed this rate with the pump and draw water below the pump or run the well dry. I don’t know if I need Specific Capacity or Well Yield Capacity or Transmissivity. I don’t need an exact answer but safe ballpark. Can you please help me figure this out, I can send additional measurements, well construction and the well stratigraphic log if needed. This is a confined aquifer more likely leaky confined, no observation wells were used. I’ve tried AQTesolv but need observation wells, I built a potentiometric surface map based on public available well logs to determine direction of groundwater flow and in case I need to determine a hydraulic gradient. I’m not sure what math equation, so many models or what additional information is needed for a safe ballpark estimate since I don’t have observation wells available for a more exact answer. It looks like Driscoll, 1986 determine a mathematical estimate to determine well/aquifer characteristics from a single pumped well without observation wells but not sure if this is what I need.

Transmissivity is what you are looking for, I think, but my experience has been that since aquifers are never homogenous, models may get you in the ballpark, but they do not take the place of an actual pumping test. You can also run into boundary conditions, well interference, anisotropy, and other factors that can impact your results. It sounds like your pumping test had a reasonable drawdown, but you did not say if you ever reached steady-state conditions. The recovery test was acceptable, but it took the full 24 hours or more to get back to static water level, even though the initial recovery was pretty quick. With a confined or semi-confined aquifer, you could use the Theis equation to calculate time vs drawdown and distance vs drawdown and that may be your best bet. By the way, you can estimate transmissivity from Specific Capacity and then back-calculate Hydraulic Conductivity from there since you know the aquifer thickness. I’d probably get a pump with more capacity and do a step test to see if you can get to 15-20 gpm – maybe 4 steps at 1-2 hours each

Regarding maximum well yield: does the formula max yield=specific capacity x available drawdown hold for both confined and unconfined conditions? When calculating max yield for a well in a confined aquifer, does one use Sc x (depth to the pump bowls measured from the bottom of the confining layer); or does one multiply Sc x (distance from top of water above the confining layer to the pump bowls)? Thanks.

Generally that holds true, since using specific capacity is basically an estimate that gets you in the ballpark. A more accurate assessment of aquifer yield would be accomplished using an actual pumping test. The pump depth setting is really going to dictate your available capacity since a pump is never going to pull water up, so the depth of the pump bowls will limit available drawdown. It’s some of the reasons we never advocate for a large “basement” below the pump setting.

How can the specific capacity be used in place of the maximum yield of a borehole

The specific capacity is measured in gallons per foot of drawdown and is mainly used to monitor the performance of the well over time. You can get an approximation of the maximum pumping rate as discussed in the second section of the blog post, but calculating the maximum yield of the well would be best done by conducting a step pumping test.

Tom,

I deal with private water supply wells in Pennsylvania, and groundwater flows mainly through water-bearing fractures. Sometimes the water may be flowing laterally through semiconfined coal seam aquifers in which the coal seam has a thick underclay. I have been able to conduct detailed recovery tests on wells by pumping the water down to the pump intake, have the homeowner shut off the pump, and then let the pressure transducer record the rising water levels up to the post-pumping static water elevation. If my recording intervals are detailed enough, I can identify where the groundwater(s) is coming into the well, sometimes at more than one location in the borehole.

In any event, I have a question regarding specific capacity calculations in private wells in which the homeowner’s submersible pump cannot draw the water down very far, so the drawdown is only within the upper part of the recovery curve where the pumping equilibrium is achieved. I do not see how a specific capacity value from drawdown near the top of the recovery curve would be of any value (except for comparing with similar tests in the future). Is it not best to pump the water down to just above the main aquifer at depth and achieve a pumping equilibrium there?

For example, in a well I just tested, the water fell just 6.5 feet before achieving a pumping equilibrium at a discharge rate of 7.5 gpm. For this segment of drawdown, the specific capacity is 1.15 gpm/ft. The total available drawdown (to the pump intake) is about 50 feet. I cannot imagine that the well yield would be 1.15 x 50 = 58 gpm. I bet that if I could increase the pumping rate to twice that (about 15 gpm), the drawdown would fall close to (or below) the pump intake. Most wells in my area of the Pennsylvania coal region recover at a maximum rate of between 2 and 10 gpm.

You put your finger on one of the weaknesses of using specific capacity. In general, if you are using specific capacity to track well performance over time, the conditions of measurement should be approximately the same each time you measure. SC works best if you are pumping somewhere near your optimal pumping rate established by a pumping test, which you have done. My guess is if you pumped more to draw down more, you would not achieve steady state conditions, although there are cases where people thought they had reached equilibrium, but step testing showed that they could have achieved steady state conditions at a higher pumping rate with more drawdown. I suppose that could happen in the case of a fractured bedrock aquifer with multiple water-bearing fracture zones with different heads. The bottom line is, if I am looking at monitoring well performance, specific capacity is good enough if you can’t do anything else, but I usually recommend monitoring a number of parameters to account for issues such as you have pointed out here. Thanks for the comment and the good information – it really adds to the discussion!

Thomas have you ever been asked to put a monetary value on a high producing(greater than 100gpm) well for real estate purposes? What documentation from a certified can be added to listing information? Thank you for your informative discussion

That would be challenging because so much of it depends on what you would do with the excess water, assuming you only need something like 10-12 gpm for residential use and some limited agriculture. Also, the condition of the well and pump would come into play. With a residential well, the value is really the replacement cost of the well and maybe some extra consideration for a reliable water supply.

Thomas,

Thanks for the informative write up. Can specific capacity determine the useful life of a well? I have seen some rough figures where rehabilitation is recommended after a 10-20% decline, and a more intensive rehabilitation is required around a 40% decline. Is there a threshold where rehabilitation is no longer helpful and well replacement is needed instead?

Generally, yes – the ranges you mention work reasonably well for determining rehab intervals, although I typically go with some other factors in addition to specific capacity. As far as useful life – it really depends on how low you can go on production before it is no longer worth it. Some people try to squeeze out any remaining life they can out of the well even though SC is low. Usually when you get down to end of life, there are other factors that contribute to the decision to retire a well, including corrosion issues and other loss of well integrity. As seen in the blog post, you can plot the SC over time and see where you are headed, so that should give you a good approximate of the remaining life of the well.

I’m not sure specific capacity can determine the useful life of a well other than to measure the intervals between rehabilitation events and how much capacity you restore at each rehabilitation. From that, you can make a rough determination of when your specific capacity might get to zero. Of course, you would want to replace the well before it gets to zero, obviously, so the question is what is the point that further rehabilitation makes no sense and it is time to replace the well. This is why it is important to track and graph SC on a regular basis so you can see what both your short term and long term trends are. Also, measuring SC right after a well rehabilitation is important to re-establish the baseline and help plot long term trends. Since SC is relatively easy to measure, I recommend taking measurements monthly. or at least quarterly, and put them on a graph so you can visually see the trends.

As far as the useful life of a well, there are many factors that can impact that the life of a well, such well construction, regular well rehabilitation, water chemistry, etc. I recommend, for municipal wells, conducting an annual testing process that goes beyond specific capacity and looks at a full range of chemical and microbiological factors that can impact well performance and longevity. I also recommend routine well videos – at least every few years. All that can get a pretty good handle on the remaining lifespan of the well.

What is your opinion if reporting values of well efficiencies exceeding 100% with actual vs. theoretical specific capacities?

I think you are confusing specific capacity and well efficiency. They are related, but specific capacity is really more of an indirect measure of well efficiency and is measured using gallons of discharge divided by drawdown in feet, i.e. gallons per foot of drawdown. Specific capacity will change over time as the well plugs or experiences other factors that decrease the flow of water to the well under pumping conditions, so by measuring SC over time, you can generally determine the rate of plugging in a well. SC is also relatively easy to measure, so it is a handy tool to measure well performance and give us an idea of when it is time to rehab a well.

Well efficiency is the ratio of actual versus theoretical drawdown and is usually measured during a pumping test with an observation well. A 100% efficient well means that actual drawdown equals theoretical drawdown and that is just not going to happen in an actual well, even a brand new one. Whether it is water flowing the screen or gravel pack. plugging in the well, or turbulent flow, there is always going to be some resistance that is going to make the well less than 100% efficient. If you get 80-90 percent efficiency in a new well, you are doing pretty well. If you are exceeding 100% efficiency, there is something wrong with the calculation somewhere – likely in the calculation of the theoretical drawdown would be my best guess.