Step 1: Understand what nitrates are, why they matter, and the regulatory framework

Nitrate (NO3-) is one of the most common man-made contaminants in groundwater. In water-supply practice we often report nitrate as nitrate-nitrogen, written as nitrate as N. The U.S. Environmental Protection Agency sets the federal maximum contaminant level at 10 milligrams per liter as nitrate-nitrogen (10 mg/L as N). Nitrite has its own level and is regulated differently, but nitrate is the main focus for most groundwater supply concerns.

Why nitrate is a public health concern. Acute exposure to high nitrate levels is associated with methemoglobinemia in infants, sometimes called Blue Baby Syndrome. Sensitive groups include infants under six months, pregnant people, and individuals with certain enzyme deficiencies. There is emerging research exploring longer-term associations between nitrate exposure and reproductive or cancer outcomes. That research is ongoing, so conservative management and prevention remain the prudent approach for utilities and private well owners.

Regulatory essentials. Nitrate exceedances trigger Tier 1 public notification requirements at the federal level, meaning systems must notify customers quickly—typically within 24 hours for an MCL exceedance. The legal citation is 40 CFR Part 141 (National Primary Drinking Water Regulations). States may have additional rules or different phrasing, so always confirm with your state primacy agency for details and templates for public notice.

“The most cost-effective path is to prevent and minimize entry. Well integrity and source protection are really where you want to go.”

Step 2: Identify the sources of nitrate loading in your area

Nitrate in groundwater generally comes from two broad categories: non-point sources and point sources. Understanding which category dominates in your service area is crucial to choosing the most economical and effective response.

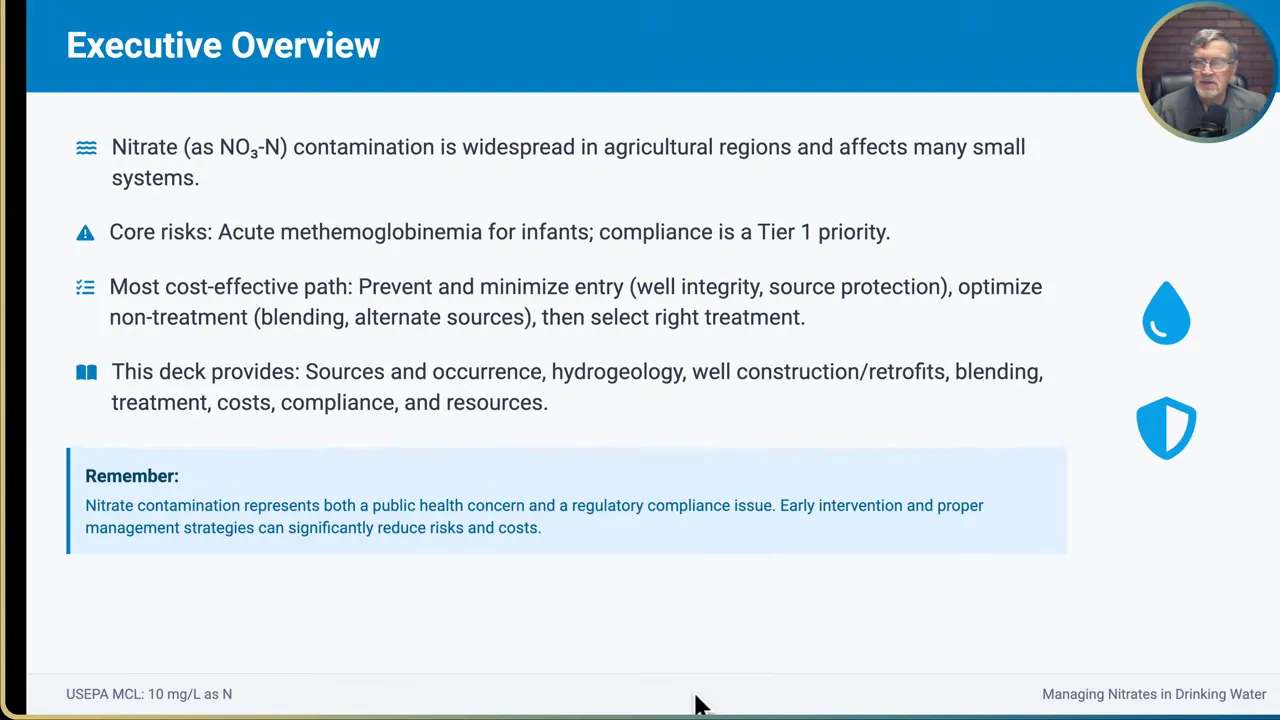

Non-point (regional) sources. Agricultural fertilizer applied across broad cropland areas is the dominant regional source in many intensive farming basins. Studies in large agricultural regions show that cropland fertilizer and cropland manure together can account for over 90 percent of regional nitrate loading. This is typical in places with significant row-crop, vegetable, and orchard production. Key risk factors for leaching include over application, inappropriate timing relative to crop uptake, inefficient irrigation practices (flood irrigation or poor timing), and shallow groundwater that shortens travel time to the aquifer.

Point (local) sources. Point sources can create severe local hotspots and include septic systems, wastewater treatment plant percolation basins, manure lagoons, feedlots and corrals, fertilizer storage and mixing spills, and high-density animal housing. In urban or peri-urban areas, clusters of septic systems or poorly designed infiltration basins can elevate nitrate locally.

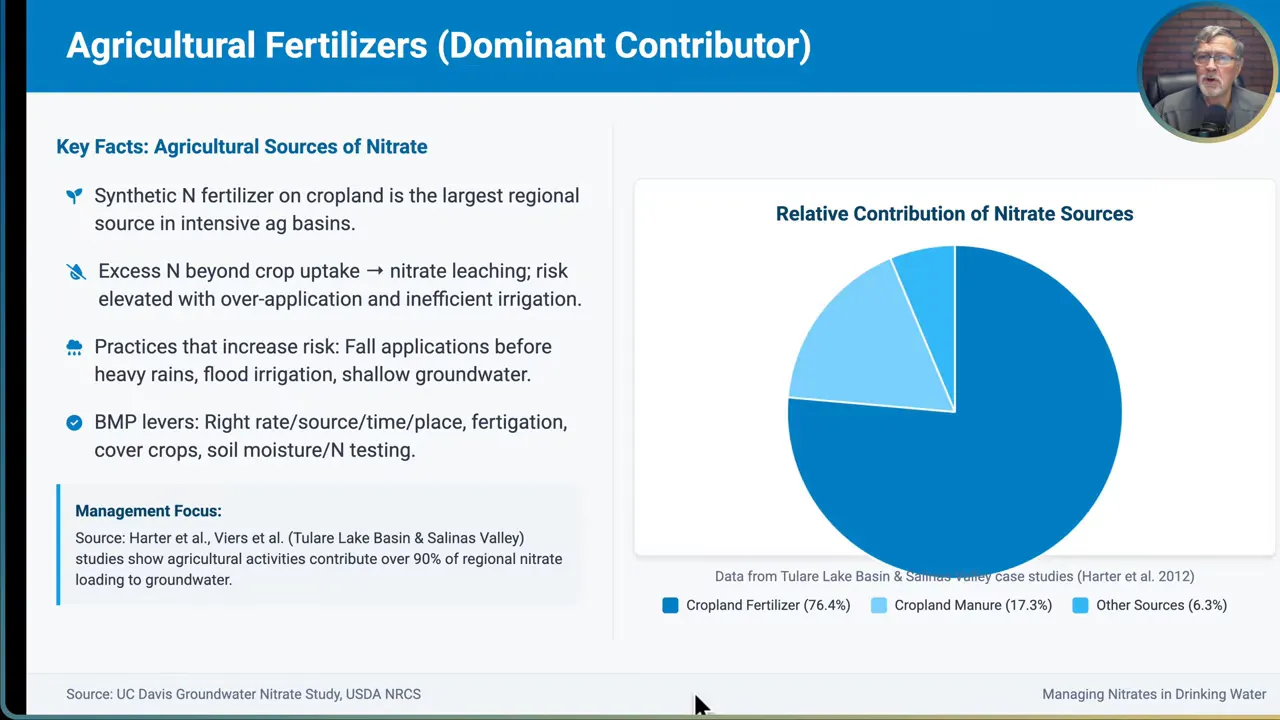

How nitrate reaches the aquifer. Most nitrate starts on the surface, infiltrates through the unsaturated zone (vadose zone), moves by advection with groundwater, spreads by dispersion, and may reach drinking water wells after years or even decades. Well-bore conduits and improperly sealed wells can accelerate contamination transport by short-circuiting surface or shallow sources directly into deeper production zones.

Step 3: Assess hydrogeology and understand nitrate transport and attenuation

Nitrate is a highly mobile ion in groundwater. It is conservative in oxic environments, meaning it does not readily adsorb to aquifer material and does not degrade quickly without special chemical or biological conditions. Two fundamental transport processes govern nitrate migration:

- Advection: the bulk movement of nitrate at the same rate as groundwater flow.

- Dispersion: spreading of the nitrate plume because of heterogeneity in flow paths and velocities, which dilutes concentrations but does not significantly reduce the mass unless denitrification occurs.

Preferential pathways and well conduits. Fractures, coarse sediments, karst features, well annuli and improperly sealed casings create faster transport paths and irregular plume shapes that may reach wells more quickly than expected. This is why local geological knowledge and careful well construction are key.

Natural attenuation: denitrification. Denitrification reduces nitrate to nitrogen gas, but it requires two things: anoxic (reducing) conditions and an electron donor (usually organic carbon or reduced minerals like pyrite). Many alluvial aquifers used for drinking water are oxic near the surface and lack sufficient electron donors, so natural denitrification is limited or absent. Therefore, nitrate concentrations can persist for decades and continue to migrate from the vadose zone through groundwater. Do not assume natural attenuation will solve your compliance issues unless you have site-specific evidence: measure dissolved oxygen, oxidation-reduction potential, and indicators of organic carbon and reduced minerals to confirm denitrification potential.

Step 4: Delineate well capture zones and evaluate groundwater vulnerability

Delineating the capture zone for each production well is the most practical way to prioritize source protection. Capture zone delineation shows the land area that contributes groundwater to the well within a given timeframe (for example, 1-, 5-, or 25-year capture zones). That information guides targeted field work like:

- Identifying nearby feedlots, septic fields, fertilizer storage facilities, or agricultural fields with frequent fertilizer application.

- Prioritizing landowner outreach and best management practices within the capture zone.

- Placing monitoring wells to detect early changes before the water reaches the production well.

Factors that increase groundwater vulnerability include a shallow water table, high soil permeability, and coarse-grained aquifer materials. Clay layers and aquitards can provide vertical protection by slowing downward migration, but they are not an absolute barrier if wells are screened across multiple aquifers or if there are conduits. Multiple-aquifer screened wells can short-circuit contamination into deeper strata. Make sure your well design and capture zone mapping reflect real hydrogeologic conditions rather than assumptions.

Step 5: Inspect wells, prioritize well construction and well integrity fixes

Well construction and integrity are your first line of defense. A properly constructed well with an adequate continuous annular seal grounded in low-permeability material can prevent vertical leakage of surface and shallow sources. Essential well features to review include casing, screen, annular seal, sanitary wellhead, pad slope, pitless adapter and vermin-proof cap.

Annular seals. Public water supply wells commonly require a standard annular seal depth like 50 feet, but that is a minimum. Sealing should be based on geology: the annular seal must extend into a sufficiently impermeable layer (clay or rock) that isolates contaminated upper zones. If the nitrate-affected zone sits at 100 feet, a 50-foot seal leaving the upper contaminated zone open will not protect your well.

Common problems. In my experience, the vast majority of nitrate occurrences in supply wells trace back to improperly installed or failed annulus seals, multi-aquifer screens, or poor sanitary protection at the wellhead. When a system calls for help with a nitrate problem, the first document to request is the driller log. A log often reveals screened intervals, seal depths, and potential design issues that explain elevated nitrate concentrations.

Step 6: Implement targeted well retrofits and protective actions before treating

Before you commit to an expensive treatment plant, evaluate whether the nitrate source can be excluded from the pumped zone by retrofitting the well. Common retrofit options include:

- Internal liners: install a liner within the existing casing to isolate shallow or contaminated intervals from your screened production interval.

- Inflatable packers: temporarily isolate sections to help determine productive, low-nitrate zones and support longer-term sealing strategies.

- Downhole sealing: add grout/seal material in the annulus to extend or repair seals where mechanical failure occurred.

- Adjust pump intake depth: if vertical stratification exists and deeper water is lower in nitrate, move the pump intake down to target better quality water.

- Install variable frequency drives: VFDs help manage well drawdown and seasonal fluctuations while targeting preferred zones and minimizing entrainment of contaminated layers.

Vertical profiling and mass balance. Use downhole profiling tools to measure nitrate concentration, dissolved oxygen, and conductivity by depth. This tells you which interval contributes the bulk of nitrate and whether sealing or intake relocation will be effective. Always perform a mass-balance analysis: sealing off a shallow zone may reduce production capacity. Weigh the production loss against the benefit of avoiding treatment, and evaluate combined strategies like pairing well modifications with blending or interconnections.

Abandon unused wells. Nearby abandoned or improperly sealed wells often act as conduits for contamination. Locate and properly abandon them to remove potential leakage paths. Maintain a proper sanitary wellhead: a raised pad, pitless adapter correctly installed, and a vermin-proof cap to prevent direct surface contamination.

Step 7: Pursue non-treatment options aggressively: source control, blending, and alternative supplies

Non-treatment options are usually the most cost-effective. They can be implemented alone or together, and they often avoid the long-term operational burden and residuals management that treatment systems create.

Source control. Engage with local growers, ranchers and the septic-owner community. Promote nutrient best management practices (BMPs): right rate, right source, right time, right place. Encourage fertigation and precision agriculture techniques to prevent over-application. Promote cover crops and soil testing to consume and retain excess nitrogen during fallow periods.

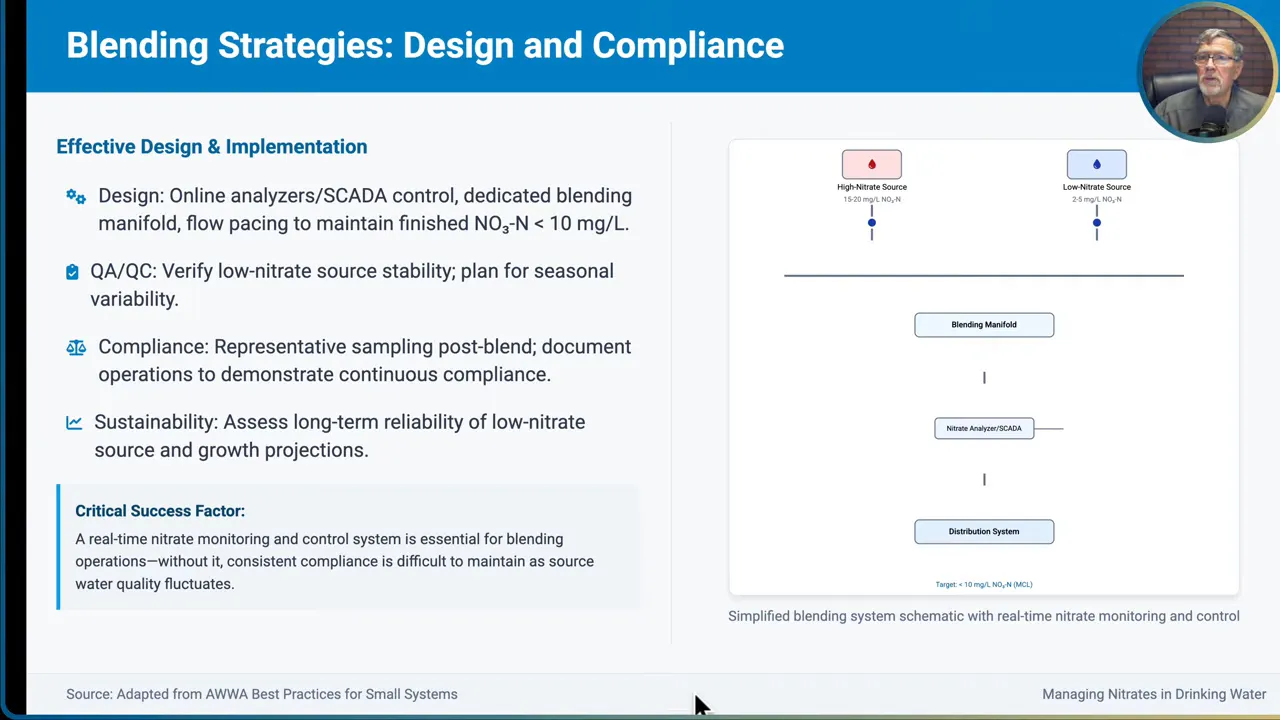

Blending. If your system has both high- and low-nitrate sources, building a blending manifold is a practical solution. Blending dilutes high-nitrate water with low-nitrate water to meet the MCL. Blending requires design care and operational controls:

- Install online nitrate analyzers on the input streams and the blended effluent.

- Integrate analyzers with SCADA for real-time control, cloud storage, alarms, and remote access.

- Plan for seasonal variations in source quality and flow so your blending ratios maintain compliance under all operating conditions.

- Perform a compliance monitoring plan and document the blended flows and concentrations for regulatory reporting.

Blending math example. Suppose you have a high-nitrate source at 20 mg/L as N and a low-nitrate source at 2 mg/L as N. Your target is 10 mg/L as N. Let Qh be the high-nitrate flow and Ql be the low-nitrate flow. The mixing equation is:

- 10 = (20*Qh + 2*Ql) / (Qh + Ql)

- Solve for Ql/Qh: 10*(Qh+Ql) = 20*Qh + 2*Ql → 10Qh + 10Ql = 20Qh + 2Ql

- Rearrange: 8Ql = 10Qh → Ql/Qh = 10/8 = 1.25

- So you need 1.25 times as much low-nitrate water as high-nitrate water to achieve the 10 mg/L target.

Operational implications. You must be able to deliver the required low-nitrate flow reliably. In practice, SCADA control tied to online analyzers automates this and provides the documentation regulators require.

Alternative supplies and regionalization. Consider drilling a new deeper well into a lower-nitrate zone, interconnecting with neighboring utilities, or participating in regional water supply projects. Interconnection may be the fastest and most economical way for small systems to protect public health and avoid long-term plant operation costs.

Step 8: If treatment is required, evaluate technology options carefully

Treatment should be the last resort after all feasible non-treatment options have been exhausted. If treatment is necessary, choose the correct technology based on source water quality, production scale, disposal constraints, and operator capacity. Main technologies for nitrate removal include:

- Ion exchange (IX): Preferential for low to moderate nitrates. IX replaces nitrate ions with chloride or another exchanger ion and requires chemical regeneration or brine disposal. IX tends to be the most cost-effective per unit volume for many community water supplies, but it creates a concentrated brine waste that must be disposed of legally.

- Reverse osmosis (RO): Highly effective and removes many contaminants beyond nitrate, including TDS and certain organics. RO is energy-intensive, has high capital costs, and generates concentrate requiring disposal. RO can be applied as central treatment or point-of-entry/point-of-use (POE/POU).

- Biological denitrification: Uses microbial communities to reduce nitrate to nitrogen gas. It avoids brine concentrate but is operationally complex, requires controlling carbon sources and redox conditions, and raises concerns about bacterial regrowth in distribution systems if not carefully managed. High operator skill and intense monitoring are required.

- Electrodialysis: Electrochemical separation that can be effective for certain feedwaters. It requires electricity and has specialized maintenance needs.

Selection factors and small-system issues. Small systems face economy-of-scale disadvantages: per-unit costs are often higher for small plants, and operator availability for intensive processes may be limited. Consider point-of-use systems for a small number of affected residences, or a hybrid strategy where treatment is targeted for sensitive populations while other non-treatment measures protect broader supply.

Waste residuals. Regeneration brine from ion exchange and concentrate from RO are significant considerations. Disposal options vary by region and may include deep well injection, industrial wastewater disposal, municipal treatment if acceptable, evaporation ponds permitted appropriately, or beneficial reuse where feasible. Costs and permitability of residuals disposal can determine the viability of a technology more than its capital price.

Step 9: Run pilots, do lifecycle cost analysis, and plan financing

Before committing to capital projects, always pilot the chosen technology at a representative scale. Piloting helps determine real removal rates, chemical requirements, waste volumes, operational labor, staffing needs, and maintenance burdens. A pilot can also reveal seasonal performance limitations and other practical constraints.

Life cycle cost analysis. Compare capital expenditures (CAPEX) and operating expenditures (OPEX) across alternatives over the asset lifetime (for example, 20 to 30 years). Include the following in OPEX:

- Chemicals and media replacement

- Energy and labor

- Waste residual handling and disposal

- Regulatory monitoring and reporting

- Planned replacement cycles and contingency repair

Often, a new deeper well or a well modification combined with blending will be cheaper on a lifecycle basis than building and operating a treatment plant. But there are exceptions: where multiple contaminants exist (for example, nitrate plus arsenic or high TDS), reverse osmosis may be the most flexible single-technology solution.

Funding sources. Check state revolving funds, USDA Rural Development loans and grants, local bonds and levies, and public-private partnerships. Leasing or vendor financing can provide bridge funding. Small systems can often partner with regional entities to reduce per-unit costs.

Step 10: Design a robust monitoring, compliance and response plan

Monitoring frequency. Federal baseline monitoring frequencies are annual for groundwater and quarterly for surface water systems. When concentrations approach the MCL or show variability, increase monitoring frequency. If you implement blending or treatment, continuous online monitoring of influent and effluent streams is strongly recommended, with laboratory confirmation samples as required by your state primacy agency.

What to measure. For nitrate management, include these parameters in routine monitoring and trend analysis:

- Nitrate as N

- Nitrite as N

- Dissolved oxygen and oxidation-reduction potential

- Sulfate and chloride

- Specific conductance

- Total organic carbon or surrogate parameters for available carbon

- Depth-specific profiles during well assessments

Recordkeeping and data-driven management. Maintain at least 10 years of chemical analyses where required and three to twelve years for operational records, depending on state rules. Digitize records and integrate monitoring data into a SCADA or cloud-based archival and reporting system. Trend analysis is more valuable than isolated snapshots. Trends reveal seasonal patterns, increasing or decreasing trajectories, and the effects of interventions such as BMP adoption or well retrofits.

Public notification and emergency response. Prepare pre-drafted Tier 1 public notification templates and a nitrate-specific emergency response plan. The plan should include:

- Immediate public notice logistics and templates

- Alternate water supply arrangements for sensitive populations (infants and pregnant people)

- Short-term operational steps such as source shutdown, blending adjustments, or bottled water distribution

- Investigation steps and timeline for corrective actions

- Staff responsibilities and contact lists

Step 11: Operator readiness, SOPs and asset management

Operators must be ready to operate whichever solution you choose. Develop standard operating procedures for blending operations and for plant upsets. Maintain a spare parts inventory and have vendor support contracts for specialty components (pumps, analyzers, control systems). Provide training for staff on nitrate-specific monitoring and response actions.

Well asset management. Implement routine inspections, schedule video logging and sonic seal integrity tests as needed, and program proactive seal repairs before failures cause contamination. Video logging detects casing damage, screen collapses, and biofouling. Sonic and other integrity tests reveal annulus anomalies without full-scale dismantling.

Step 12: Best management practices for the watershed and community engagement

Because agriculture is frequently the dominant source at the regional scale, watershed-level solutions are often required. Encourage and participate in the following:

- Engaging growers and ranchers in nutrient management and irrigation efficiency programs.

- Facilitating soil testing and precision nutrient application.

- Promoting cover crops and other practices that retain nitrogen on the land during non-growing seasons.

- Working with local planning departments to assess cumulative impacts of on-site septic systems and other point sources.

- Collaborating on regional monitoring networks to track nitrate trends across the aquifer.

Community outreach and transparency. Keep customers and stakeholders informed about nitrate trends, what actions are being taken, and how they can help. If source control measures are being implemented on agricultural lands, explain expected timelines: groundwater responses to improved on-farm practices can lag by years or decades because nitrate stored in the vadose zone and slow groundwater transit continue to feed plumes.

Step 13: Practical checklists and field tactics

Use the following checklists to build an action plan for a system with a nitrate exceedance or with elevated nitrate that risks exceedance.

Quick diagnostics checklist

- Obtain driller logs and well construction diagrams.

- Run depth-specific water quality profiles for nitrate, DO, ORP, conductivity, and temperature.

- Inspect wellhead for sanitary defects and open conduits.

- Locate nearby potential sources in the well’s capture zone (feedlots, septic fields, cropland, lagoons, fertilizer storage) and prioritize them.

- Review historical land use and fertilizer application data if available.

Immediate operational checklist for an exceedance

- Issue Tier 1 public notice within regulatory timeframe.

- Activate emergency response plan for alternate supplies to sensitive populations.

- Collect confirmatory samples and begin intensified monitoring schedule.

- Evaluate blending options if other sources are available.

- Notify state primacy agency and request technical assistance if needed.

Long-term project checklist

- Delineate capture zones and conduct a source inventory.

- Pilot retrofit and treatment alternatives and run lifecycle cost comparisons.

- Implement source protection and BMPs with landowners in capture zones.

- Install continuous analyzers and SCADA integration for blending or treatment control.

- Budget for residuals management and include in capital and operating plans.

Step 14: Resources, contacts and tools

You do not have to navigate nitrate management alone. Useful organizations and resources include the U.S. EPA, American Water Works Association, National Rural Water Association, and your state primacy agency. Many states and regional rural water associations provide circuit riders, technical assistance, and funding guidance for small systems. Consider contacting universities or extension services for BMP outreach programs and technical guidance on agricultural nutrient management.

Core technical tools and tests you will routinely use:

- Online nitrate analyzers and laboratory confirmation with certified methods

- SCADA with cloud storage and alarm capability

- Downhole sampling and vertical profiling tools

- Video logging and sonic seal integrity testing

- Pilot-scale treatment trains and bench-scale denitrification tests

Key takeaways and closing guidance

Managing nitrate in drinking water is multifaceted and begins upstream with source protection and good hydrogeology-informed well construction. Agriculture is often the largest regional contributor and requires coordinated watershed solutions, but local point sources and well integrity failures often explain sudden or localized exceedances. Prevent and minimize entry into the aquifer first. Well integrity and capture zone management are usually the most cost-effective measures. Retrofitting a well or drilling a deeper well and blending sources often beat long-term treatment on a lifecycle-cost basis. When treatment is necessary, make the technology choice based on whole-life costs, residuals management, operator capability and compliance burden.

Finally, use data: monitor more often as you approach the MCL, digitize your records, and use trend analysis to guide decisions rather than single samples. Prepare your public notification and emergency plans in advance so when a problem occurs you can protect sensitive populations immediately and then pursue long-term, sustainable solutions.

Selected references and next steps

- Review regional studies and case work that focus on agricultural basins and nitrate loading to better understand local patterns.

- Engage hydrogeologic expertise to delineate capture zones and to design wells and seals based on geology rather than a one-size-fits-all seal depth.

- Work with local agricultural extension and growers to promote BMPs, cover crops and precision fertilizer application to reduce long-term aquifer loads.

- Pilot any treatment or retrofit strategy and evaluate total cost of ownership before committing capital funds.

- Maintain a proactive monitoring and emergency response plan and keep the community informed.

If you follow these steps—assessing sources, protecting and repairing wells, using non-treatment strategies like blending where possible, piloting technologies when necessary, planning for residuals and costs, and maintaining robust monitoring and public communication—you will be in the strongest position to manage nitrate risks to your drinking water system without unnecessary cost or regulatory surprises.

Additional resources

- EPA Drinking Water Requirements and guidance

- State primacy agency nitrate guidance and compliance templates

- Local rural water associations and circuit riders for small-system technical assistance

- University extension programs for nutrient management and cover crop guidance