This guide breaks down the Lead and Copper Rule Improvements (LCRI) into a clear, step-by-step plan for small water systems. If you operate, manage, or advise a small community water system, you must be ready: the regulatory clocks are running, the requirements are firm, and there are specific milestones and documentation expectations you cannot ignore. This article walks you through background, deadlines, inventories, sampling, replacement programs, public communications, funding options, and practical tools you can adopt right now to stay compliant and protect public health.

Step 1: Understand the shift—why LCRI matters

The regulatory approach has moved from managing corrosion to removing the source of lead exposure. Under the original 1991 Lead and Copper Rule, the primary compliance tool was corrosion control. The action level was 15 parts per billion at the 90th percentile and utilities relied heavily on water chemistry and corrosion control strategies to keep lead in tap water below that threshold.

That approach showed its limits in cases where water chemistry changed suddenly and existing corrosion protections failed. The most notable example highlighted the risk: a change in treatment can remove protective scale and mobilize lead into drinking water. That failure triggered a national re-evaluation of whether corrosion control alone is enough. The LCRI represents a paradigmatic shift: identify and map service lines, increase transparency, and replace lead sources.

What LCRI does differently

- Requires comprehensive, publicly accessible service line inventories.

- Mandates replacement of lead service lines (LSLs) and galvanized requiring replacement (GRR) lines within a 10-year window.

- Lowers the lead action level from 15 ppb to 10 ppb at the 90th percentile.

- Strengthens sampling protocols, including dual sample collection (first liter and fifth liter) at LSL taps with the higher result used for compliance.

- Requires prompt public notification and stronger outreach, particularly to schools, childcare facilities, and vulnerable populations.

This shift is not optional. It is a national public health mandate and it affects budgeting, asset management, and community engagement. Smaller systems have some limited flexibilities, but the baseline obligations remain firm.

Step 2: Know the critical deadlines and the 10-year replacement clock

Deadlines are central to LCRI compliance. There are several dates you must track and meet. The key ones are summarized below, with the two most consequential being the baseline inventory due date and the final completion deadline for replacements.

- October 16, 2024 — Initial service line inventory and the start of Tier 1 24-hour notification for action level exceedances. If you missed this one, document why and move quickly to complete the initial inventory.

- December 30, 2024 — LCRI became effective as published in the Federal Register.

- November 1, 2027 — Baseline inventory due. This is a more comprehensive inventory than the initial submission and triggers the start of the 10-year replacement clock.

- November 1, 2037 — Deadline to complete replacement of all lead and GRR service lines that require replacement unless a state-granted extension applies.

Once November 1, 2027 arrives for your system, you must replace an average of 10 percent of your LSLs and GRRs per year to comply with the 10-year mandate. Extensions can be requested, but they are generally reserved for high-density replacement burdens and require state approval with robust documentation of financial hardship or other justifying circumstances.

Step 3: Build your foundation—service line inventories and classification

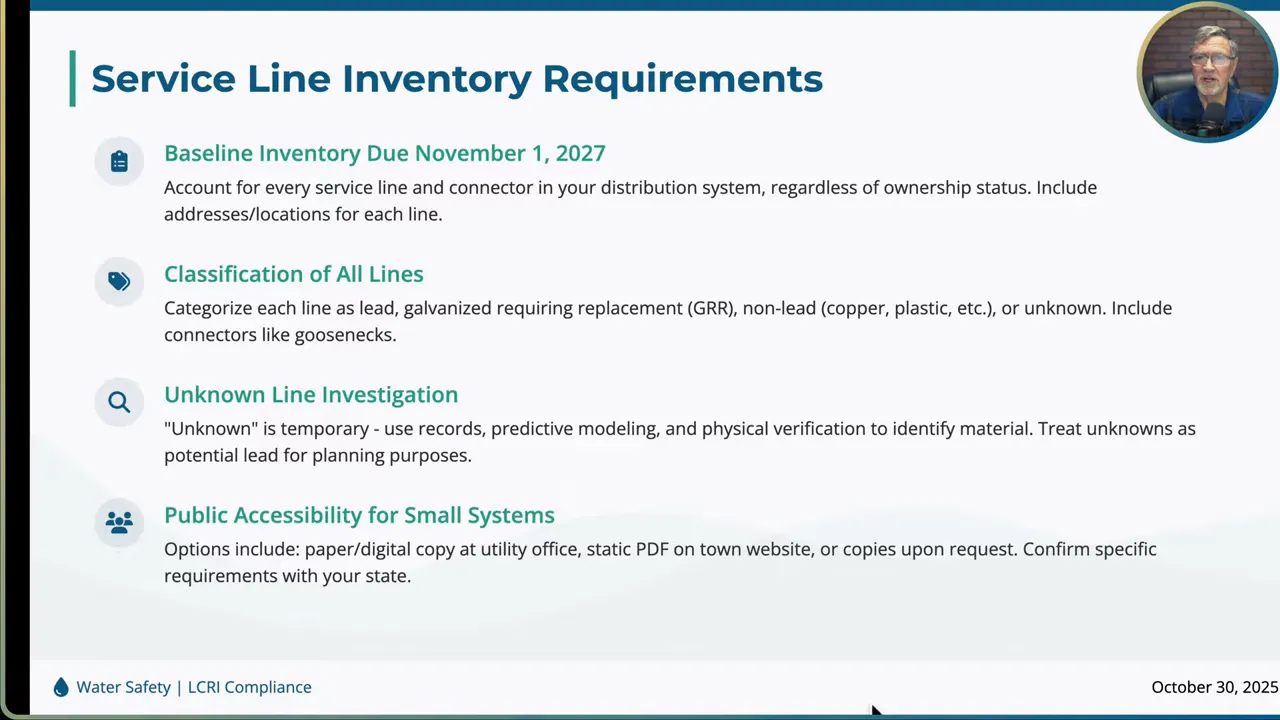

Your baseline inventory is the foundation for everything that follows. Without accurate identification of each service line and connector, you cannot properly prioritize replacements, estimate costs, or demonstrate compliance.

What the baseline inventory must include

- Every service line and connector in the distribution system, regardless of ownership.

- Precise addresses and location information for each service line.

- Classification of each line into one of: Lead, GRR (galvanized requiring replacement), Nonlead (copper, plastic, etc.), or Unknown.

- Identification of connectors and materials, including fittings and couplings at the water main and building side.

- Documentation of the method used to determine line material (records review, physical inspection, predictive modeling, or field verification).

Treat unknowns as potential lead for planning. Unknowns must be investigated, documented, and resolved. If you leave a large unknown category untested, you are risking both compliance and public trust.

How to collect the data

- Start with existing records: construction files, permit logs, meter installation records, plumbing records, and historical engineering drawings.

- Use predictive models and age-based indicators: match installation dates with known material usage in your geography and time periods.

- Field verify: visible excavations, curb box inspections, hydrovac or potholing when permitted, or service valve access.

- Document assumptions: where you classify a line by inference, log the basis and plan a verification schedule.

If you have not yet invested in GIS, strongly consider it now. A spatial database will streamline inventory updates, support prioritization mapping, and be extremely helpful when reporting to your state primacy agency. If capital resources are limited, explore low-cost solutions or shared services with regional partners.

Step 4: Decide who has access and how to get consent for private side work

Service lines cross ownership boundaries. The public utility typically owns the line up to the meter or property boundary, while the private property owner controls the plumbing downstream. Here is how to approach access and consent.

Where the system has legal physical access

- The utility must replace lines where it has legal and physical control.

- For private-side replacements, utilities must document lack of access and make at least four outreach attempts using two different methods before classifying the line as inaccessible.

- Common methods: certified mail, in-person delivery, door hanger, email, phone call, and published public notices or utility board bulletins.

Keep detailed records of each contact attempt, date, method, and homeowner response. These records protect the utility if an auditor or state reviewer questions your approach to private-side replacement attempts.

Cost sharing and homeowner programs

- Review your state and local rules for allowable cost-sharing programs. Some states authorize utilities to cover full private-side replacement costs, others permit partial cost sharing, and some require homeowner-funded private-side work.

- Design equitable policies with a focus on vulnerable or low-income customers. Consider grants, revolving loan funds, or installment payment programs to limit the financial burden on property owners.

- Document your program policy and communicate it clearly to affected customers.

Step 5: Create and file a replacement plan that prioritizes public health

Your replacement plan is not just a schedule. It must be a defensible, prioritized, and documented strategy that targets high-risk, high-benefit replacements first. Schools, childcare facilities, and neighborhoods with vulnerable populations must be near the top of your list.

Required elements of the replacement plan

- Detailed prioritization schedule showing the order of replacements and justification for prioritization.

- Annual replacement targets supporting an average 10 percent per year replacement rate over the 10-year period starting November 1, 2027.

- Communications plan to secure homeowner consent and inform affected customers about work schedules and post-replacement flushing guidance.

- Property access approach and documentation procedures for inaccessible sites.

- Budget, funding strategy, and contingency planning for both capital and soft costs.

- Coordination plan with public works, streets departments, and contractors to minimize disruption and cost.

When prioritizing, consider:

- Facilities that serve children, pregnant people, or medically vulnerable residents.

- Areas with historically higher lead sampling results.

- Neighborhoods where replacement bundling yields economies of scale due to contiguous LSLs.

- Where seasonal or construction windows make work easier or cheaper.

Step 6: Upgrade sampling plans and comply with new monitoring rules

The sampling program changes under LCRI are concrete and designed to better capture lead originating from service lines. You must update your sampling plan and follow strict procedures.

Sampling changes to implement

- Dual sample collection at LSL taps: collect both a first liter sample and a fifth liter sample after a minimum six-hour stagnation period. Use the higher of the two values for compliance determination.

- Start standard monitoring for systems with LSL-GRR on November 1, 2027. Standard monitoring runs for two consecutive six-month periods unless you are already compliant under LCRI protocols.

- Prioritize schools and childcare facilities for targeted sampling and supplement routine monitoring with targeted campaigns where warranted.

- Maintain strict chain-of-custody, labeling, and sample handling SOPs to ensure defensible results.

Why first and fifth liter? The location of lead in plumbing affects how samples read. A first liter often captures water sitting in the service line or internal plumbing that is most likely to contain mobilized lead. A fifth liter might capture water from deeper in the premise plumbing. Taking both and using the higher value reduces false negatives and ensures the system captures risk stemming directly from service lines.

Monitoring frequency

- Systems with LSL-GRR must follow the prescribed tiered monitoring frequencies starting on the November 2027 timeline.

- Smaller systems may qualify for reduced monitoring frequency if they consistently show low sampling results and obtain state approval for that flexibility.

Step 7: Respond quickly and transparently to exceedances

Exceedances of the 10 ppb action level at the 90th percentile trigger immediate actions. Public notification rules are strict and time sensitive.

Action level and notifications

- The lead action level under LCRI is 10 parts per billion at the 90th percentile of required samples.

- Systems must provide Tier 1 public notification within 24 hours of learning of an action level exceedance. This is non-negotiable and requires preparedness to notify affected customers quickly.

- Notifications must explain health risks, the service line materials status, and available resources and measures the system is taking or will take.

Required follow-ups for exceedances

- Evaluate and re-optimize corrosion control treatment if appropriate and feasible.

- Implement enhanced public education and outreach emphasizing protective measures.

- Systems with multiple exceedances in a rolling five-year period may be required to provide certified lead-reducing point-of-use filters to all customers until corrective actions are completed.

Tier 1 notifications must be clear, accessible, and available in the languages appropriate for limited English proficiency (LEP) communities in your service area. Maintaining trust requires speed and clarity.

Step 8: Consider small system flexibilities carefully—and get state approval

Small systems serving 3,300 people or fewer, plus non-transient non-community systems, have limited flexibilities. These options are attractive but require state primacy agency approval and come with strict conditions.

Key small system flexibilities

- Point-of-use (POU) devices after an action level exceedance: Systems may install and maintain certified lead-reducing point-of-use devices at all cooking and drinking taps instead of re-optimizing corrosion control. This is only for qualifying small systems and requires a robust maintenance and replacement program.

- Replace all lead-bearing plumbing option: Systems that control all plumbing on the premise and have no LSL or GRR may replace non-lead-free plumbing within one year of state approval.

- Reduced monitoring frequency: Small systems with consistently low sampling results may apply for reduced monitoring frequency, up to nine years between certain monitoring events, subject to state approval.

- Simplified public education requirements: Some outreach requirements may be streamlined for qualifying small systems, but basic transparency and annual notifications remain.

Small system flexibilities do not remove the 10-year replacement mandate. They change certain operational responses but not the core requirement to eliminate lead sources within the specified timeline.

Step 9: Build a phased action plan—foundation, verification, execution

Divide your work into three phases with distinct deliverables, documentation, and timelines. This helps you secure funding, demonstrate progress to regulators, and manage the workload over a 10-year horizon.

Phase 1: Foundation planning (now through mid-2026)

- Form a compliance team and designate a lead responsible for LCRI compliance.

- Brief the utility board on scope, risk, estimated costs, and funding needs. Secure management support for a multiyear capital program.

- Complete and validate the initial LCR inventory that was due October 16, 2024. If you missed it, document the steps you are taking to come into compliance.

- Identify and quantify unknown service lines and develop an unknowns investigation plan with timelines and risk-based prioritization.

- Begin budget planning and a funding strategy. Build initial cost estimates, capital planning scenarios, and grant/loan research.

- Document everything. States and auditors will want records for any flexibility requests or extension applications.

Phase 2: Field verification and baseline inventory (mid-2026 to November 1, 2027)

- Execute field verifications and record reviews to classify unknown lines with a focus on older neighborhoods and high-risk areas.

- Prepare and finalize your baseline inventory due November 1, 2027. Ensure records include connectors and material documentation for both utility and private sides where possible.

- Develop your detailed LSL-GRR replacement plan with prioritization, communications, and property access approaches. This plan should be suitable for submission to the state primacy agency.

- Update your tap sampling plan to reflect the first and fifth liter sampling, minimum stagnation, and the new 10 ppb action level.

- Submit required documentation and plans to your state regulatory agency by the November 1, 2027 compliance date.

Phase 3: Execution, reporting, and maintenance (November 1, 2027 to November 1, 2037)

- Begin full-scale execution of the replacement program aligned to the approved plan. Replace LSL and GRR lines according to the prioritized schedule.

- Track completions meticulously and maintain an updated inventory and replacement status that is publicly accessible and updated annually.

- Maintain proactive public communication: construction schedules, disruptions, flushing guidance, and post-replacement testing results.

- If exceedances occur, follow the exceedance response plan: Tier 1 notifications, corrosion control evaluation, and providing filters when required.

- Document private-side access challenges and keep outreach records to show good faith efforts toward replacements.

Step 10: Prepare budgets, estimate costs, and secure funding

Financial planning is the make-or-break part of a successful program. Line replacements are capital-intensive and require both line-item budgeting and soft-cost planning.

Typical cost ranges and budgeting guidance

- Full-line replacement cost per service line can range from approximately $5,000 to $15,000 per line depending on location, length, restoration needs, traffic control, labor markets, and local permitting requirements.

- Soft costs – inventory investigations, design, construction management, customer coordination, permitting, legal, and communications – typically add 15 to 25 percent to the total project cost.

- Plan for a 10 to 20 percent contingency on top of your estimate to account for unforeseen subsurface conditions, private-side complications, and material cost fluctuations.

Example budget scenario

Suppose you have 200 LSLs to replace and you estimate $10,000 per full replacement. Your direct replacement cost is $2,000,000. Add a 20 percent contingency and soft costs: $2,000,000 x 1.20 = $2,400,000 total program cost over 10 years. Spread evenly, that requires about $240,000 per year, not counting inflation. Factor in an annual inflation escalation and you will need higher funds in later years.

Funding sources to pursue

- State Revolving Funds (SRF) — low-interest loans and sometimes grants. Engage early with the state SRF administrator; application cycles and ranking criteria often require advance planning.

- EPA grant programs — including targeted lead reduction funds, often focused on schools, childcare facilities, and disadvantaged communities. National pot sizes may be small relative to need, so competitive applications are crucial.

- USDA Rural Development — loans and grants for rural water and wastewater systems. This is a strong option for qualifying small and rural utilities.

- Water Infrastructure Finance and Innovation Act (WIFIA) — lower-cost financing for eligible projects when applicable.

- State and local capital budgets — some states and municipalities establish dedicated funds for LSL replacement.

- In-house revenue and rate adjustments — utilities may need to consider rate changes, surcharges, or special assessments to fund capital programs.

Engage your board early and present multiple funding scenarios. Document any grant applications and maintain contemporaneous records of funding conversations and commitments.

Step 11: Use technical assistance and tools to close capacity gaps

Many small systems lack staff, engineering capacity, or financial planning resources. Leverage technical assistance programs and local partners to bridge these gaps.

Available resources

- EPA technical assistance programs and regional assistance initiatives.

- Rural Community Assistance Partnership (RCAP) and state RCAP affiliates offering free technical assistance and planning support.

- Rural water associations and circuit riders who can provide hands-on, local assistance.

- State primacy technical assistance programs and specially funded outreach for disadvantaged communities.

- Private sector partners for GIS implementation and mapping services.

Practical tools to adopt:

- Inventory templates aligned with state reporting requirements.

- GIS or mapping platforms that tie service line locations to asset registers and sampling sites.

- Standard operating procedures (SOPs) for sampling, chain-of-custody, and field verification.

- Public notification templates and customer consent packets for private-side replacements.

Step 12: Document everything—records protect you and your community

Documentation is not optional. Regulators expect a clear paper trail that shows intent, action, and communication. Good documentation supports funding requests, extension petitions, audit responses, and public transparency.

Essential documentation checklist

- Inventory records with material classification, data source, verification status, and date.

- Photos, GIS points, and field notes for each verified service line.

- Records of outreach and consent attempts for private-side access (dates, methods, copies of letters, door hangers, emails, and call logs).

- Replacement schedules, contractor agreements, permits, and construction records including restoration receipts.

- Sampling plans and results, chain-of-custody forms, and lab reports.

- Public notification copies and translations used for LEP communities.

- Board minutes showing briefings and approvals, budget resolutions, funding applications, and grant award letters.

Document early and often. If you plan to request any state flexibility or an extension, your documentation must demonstrate a good faith effort to meet deadlines and a realistic plan for completion.

Step 13: Communicate strategically and inclusively with your community

Public trust is essential. Communicate early, often, and clearly. Stakeholder engagement reduces resistance, speeds consent, and improves cooperation during construction.

Communication best practices

- Prepare clear, jargon-free explanations of health risks and the steps the utility will take to reduce risk. Use plain language and avoid technical overload.

- Produce multilingual materials where there are limited English proficiency populations. Translate notifications and informational brochures into the key languages spoken in your community.

- Show the replacement prioritization map and schedule publicly. People want to know when their street or facility will be addressed.

- Offer multiple channels for questions and sign-ups: hotlines, office hours, community meetings, and online forms.

- Provide post-replacement guidance including flushing instructions and how to confirm the work. Offer follow-up sampling at replaced locations when feasible to demonstrate outcomes.

Include schools and childcare centers in early outreach. These facilities are high priority and often require coordination for access and timing. Work with facility managers to schedule sampling and replacement work without disrupting essential services.

Step 14: Evaluate POU devices, contractor models, and program controls

Point-of-use devices and alternative program controls can be part of your short-term hazard mitigation strategy, but they come with operational and legal obligations.

POU devices pros and cons

- Pros: Faster to deploy than full private-side replacement, can provide immediate protection at drinking and cooking taps for vulnerable households, potential cost savings for small systems if properly managed.

- Cons: Require ongoing maintenance, replacement cartridges, and a management program to ensure devices remain certified and effective. If devices fail to perform or are not maintained, legal liabilities may arise.

If you choose POU devices under the small system flexibility option, document device maintenance schedules, installation records, and periodic performance verification.

Program control options to consider

- Enterprise contracts with a single contractor for neighborhoods to maximize efficiency and price certainty.

- Neighborhood bundling to reduce mobilization and overhead costs per replacement.

- In-house crews for portions of the program if you have trained staff and predictable workloads; contractors for larger surge work.

- Procurement frameworks that include warranty and restoration standards for pavement and landscaping.

Step 15: Prepare for auditing, state reviews, and possible enforcement

Expect state primacy agencies and, in some cases, the EPA to review your documentation, sampling plans, and progress. Noncompliance can lead to enforcement and funding limitations. Prepare proactively.

Tips for audit readiness

- Keep a single master folder for LCRI documentation with dated, sequential records.

- Maintain a running log of all replacements, outreach attempts, correspondence with regulators, and funding submissions.

- Schedule internal reviews to ensure your inventory accurately reflects field conditions and sampling outcomes.

- When seeking extensions or flexibilities, assemble a dossier that demonstrates your financial analysis, prioritized schedule, and mitigation measures implemented to date.

Step 16: Sample templates and practical scripts you can use now

Below are ready-to-adapt templates for common communications and documentation. Customize these to your utility’s voice, branding, and the specific situation.

24-hour Tier 1 notification sample

We recommend posting all Tier 1 notices to your website and distributing via email, phone, and local media where possible. Translate if your service area has LEP populations.

Important Health Notice: Lead Action Level Exceeded

[Date]

[Utility Name] has learned that recent water samples show lead levels above the federal action level of 10 parts per billion. Elevated lead levels can pose serious health risks, particularly to infants, young children, and pregnant people. We are taking immediate steps to address this issue. Do not use tap water for drinking or cooking until further notice unless using certified water filters or bottled water. We will provide detailed next steps, actions we are taking, and resources for households in the coming days.

Annual inventory notification to customers

[Utility Name] Annual Service Line Inventory Update

We are required to maintain a public service line inventory that lists service line materials for addresses served by [Utility Name]. Our inventory shows your service line material as: [Lead / GRR / Nonlead / Unknown]. If your classification is unknown, we will contact you to schedule a short inspection or sampling. If your service line is identified as lead or GRR, we will include you in our prioritized replacement schedule and offer information about cost sharing and replacement options.

Private-side outreach script (door or phone)

- Introduce: “Hello, I am [Name] from [Utility]. We are conducting a program to identify and replace lead service lines to protect public health.”

- Explain: “Your property was identified as possibly having a lead service line. We need to confirm the material and discuss replacement options.”

- Offer: “We can schedule a brief check that requires access to the meter box and service line, or arrange for hydrovac verification if needed. If a replacement is needed, we can discuss cost sharing and scheduling.”

- Close: “Can I schedule a time that works for you? We will document attempts if you prefer to decline at this time.”

Step 17: Advance planning—what to do in the next 90 days

Concrete actions you can start immediately to avoid last-minute scrambling.

- Form or confirm your LCRI compliance team and designate a point person.

- Validate your initial inventory and identify outstanding unknowns. Prioritize verification for high-risk addresses such as schools.

- Start outreach planning and draft multilingual communication templates.

- Engage with state primacy agency to confirm reporting expectations and inquire about small system flexibilities if applicable.

- Initiate funding conversations with your SRF administrator and USDA or other potential funding partners.

- If you lack GIS, scope a low-cost GIS project and request quotes from providers. Start mapping critical assets and sampling points.

- Create a basic cost estimate for the number of LSLs/GRRs you expect to replace over 10 years and present to your board for capital planning.

- Document all steps and keep board minutes, staff notes, and communications in a single compliance folder.

Step 18: Long-term program controls and performance metrics

To make the program manageable, adopt program controls and indicators that signal if you are on track or need course correction.

Key performance indicators

- Percent of verified service lines in inventory (target 100% by November 1, 2027).

- Annual percent of LSL/GRR replacements (target average 10% per year).

- Number and percentage of unknowns reduced each reporting year.

- Number of Tier 1 notifications and time-to-notify metric (target within 24 hours of discovery).

- Customer satisfaction metrics for outreach and post-replacement experience.

Monitor monthly and present quarterly updates to your board. Use dashboards for transparency and adjust procurement or bundling strategies if costs rise above planned levels.

Step 19: Anticipate and plan for common challenges

Here are problems utilities commonly face and suggested mitigations:

- Private-side nonconsent: Offer cost-sharing, flexible payment plans, and clear educational materials. Document each outreach attempt and consider municipal ordinances where legally allowed.

- Funding gaps: Bundle projects to become more competitive for grants, phase replacements by priority, and consider modest rate adjustments tied to capital projects.

- Contractor capacity shortfalls: Use multi-year enterprise contracts, pre-qualified contractor lists, and regional cooperative procurement to ensure steady progress.

- Record gaps and unknowns: Prioritize field verification in older neighborhoods, use targeted hydrovac investigations, and leverage predictive modeling where physical verification is impractical immediately.

Step 20: Final checklist before submitting your November 1, 2027 baseline package

Use this checklist to confirm your deliverables are complete and defensible when you submit to the state primacy agency.

- Baseline service line inventory with classifications, connectors, and verification source for each entry.

- Prioritized LSL-GRR replacement plan with annual targets and a 10-year schedule aligned to the average 10 percent replacement rate.

- Updated tap sampling plan reflecting first and fifth liter sampling, minimum stagnation, and the 10 ppb action level.

- Communications plan and outreach templates, including translations for LEP populations.

- Funding and capital improvement plan with projected costs, contingencies, and identified funding sources.

- Documentation of outreach attempts and a policy for private-side access and cost sharing.

- Inventory and replacement database or public-facing repository prepared for annual updates.

Closing notes and where to get help

The next decade will be busy. The rule is firm and the timeline is finite. Begin now, document everything, and engage your state primacy agency early. Use available technical assistance from EPA programs, RCAP, rural water associations, and state programs. If your system is small and you are considering flexibilities, prepare a clear justification and obtain state approval before relying on those options.

Start with the inventory, plan for funding, and keep communicating. This is an asset management challenge with real public health stakes. A well-structured plan that documents reasonable, prioritized action will keep your system compliant and protect the community you serve.

This resource is intended to give you a practical, step-by-step pathway to compliance. Use the checklist and templates, adapt them for your local rules and codes, and remember: early action, clear documentation, and thoughtful communication are your best defenses.