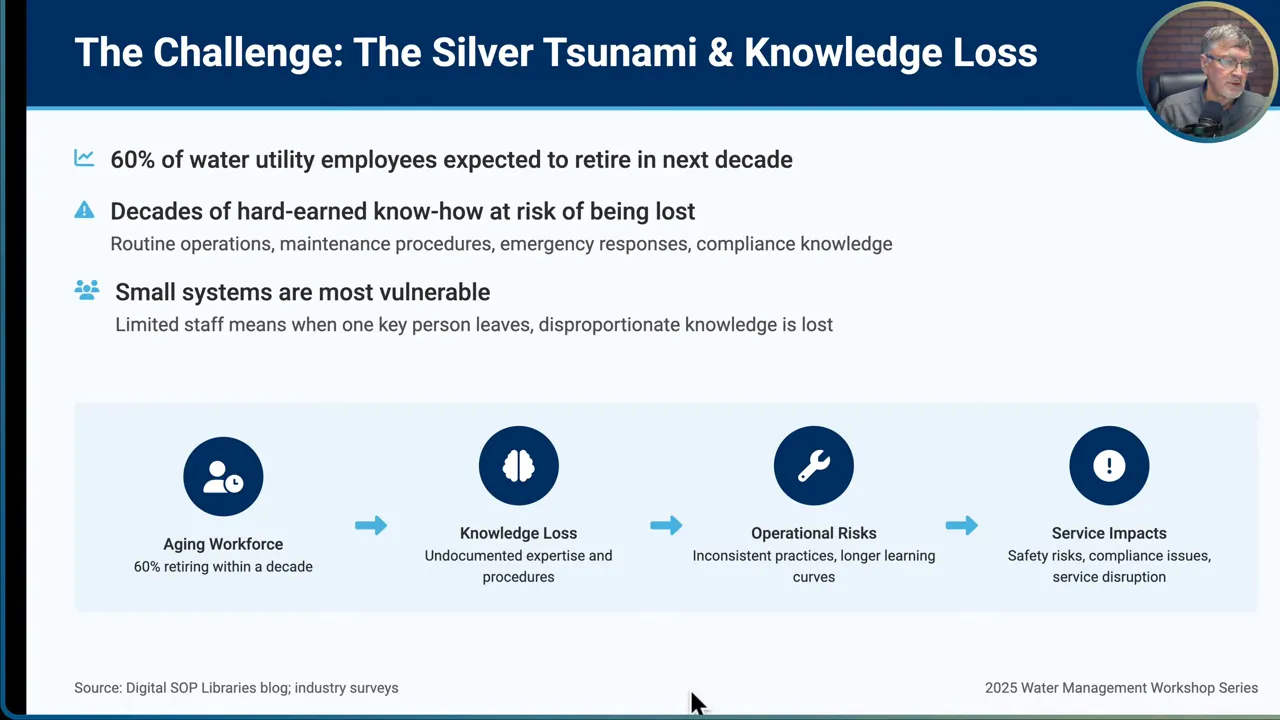

Transitioning a small water system from paper based operations to a data driven organization can feel overwhelming. There is a practical pathway that preserves institutional knowledge, reduces operational risk and builds digital capability incrementally. The starting point I recommend is building a digital Standard Operating Procedure library. This approach captures the decades of hard earned know how that often lives only in senior operators heads, converts it into accessible digital content and becomes the foundation for a broader digital transformation.

This guide is a step by step tutorial that walks through everything from picking your first SOPs to governance, video documentation and integration with SCADA and GIS. The emphasis is pragmatic. Start small. Get quick wins. Scale thoughtfully. Below are practical steps and checklists you can apply immediately, plus examples and metrics to track progress.

Step 1: Inventory and Prioritize the Right SOPs to Digitize First

The first and most important step is to identify what matters most. Not every task needs a formal SOP. Focus on the activities that have the greatest consequences for safety, compliance, service continuity or cost.

Why start by prioritizing

- Risk reduction Prevent compliance violations and dangerous mistakes by standardizing high risk procedures

- Knowledge preservation Capture veteran operator expertise before retirements create gaps

- Impact Target procedures that will demonstrate tangible benefits quickly

How to perform the inventory

- Create a simple list of all routine and critical activities across operations, maintenance and regulatory tasks

- Classify each activity by risk, complexity and frequency

- Identify which activities currently depend on one or two people to perform correctly

- Assign a priority score for SOP creation using risk, regulatory consequence and likelihood of staff turnover

What to choose for your first pilot

Pick three to five high value SOPs. Examples that typically belong in the first group are valve inspection and exercising, tank filling and level control, emergency pump station response, chemical feed and sampling procedures tied to regulatory requirements.

Step 2: Select a Cloud Platform and Establish Folder Structure

Once you know which SOPs to create first, choose a cloud platform to host the library. The right selection balances simplicity, security and future integration needs.

Platform options and considerations

- Google Workspace Easy to use, strong document collaboration, simple sharing, native Docs and Sheets for templates

- Microsoft 365 and SharePoint Integrates with Office applications, document management and team sites. It can be more complex to configure

- Dropbox Good for secure file storage and sharing, but not ideal if you need collaborative editing inside files

- Cloud SCADA vendor portals Some cloud SCADA providers offer document hosting or APIs that can feed operational data into your SOP repository

Key setup steps

- Select the cloud platform you will use

- Create an account structure with roles and permissions based on job function

- Design a logical folder hierarchy that mirrors your organizational structure or asset classes

- Agree on naming conventions and metadata tags for searchability

- Set baseline access controls and a backup policy

Folder and naming recommendations

- Top level folders by functional area: Treatment, Distribution, Sampling, Maintenance, Emergency Response

- Subfolders by asset or location: PumpStations, Tanks, BoosterStations

- Name files with a consistent structure: [Asset]_[Procedure]_[Version]_[Date] Example: TankA_LevelControl_v1.0_2025-03-01

- Create a metadata schema for keywords: asset_type, criticality, SOP_owner, review_date

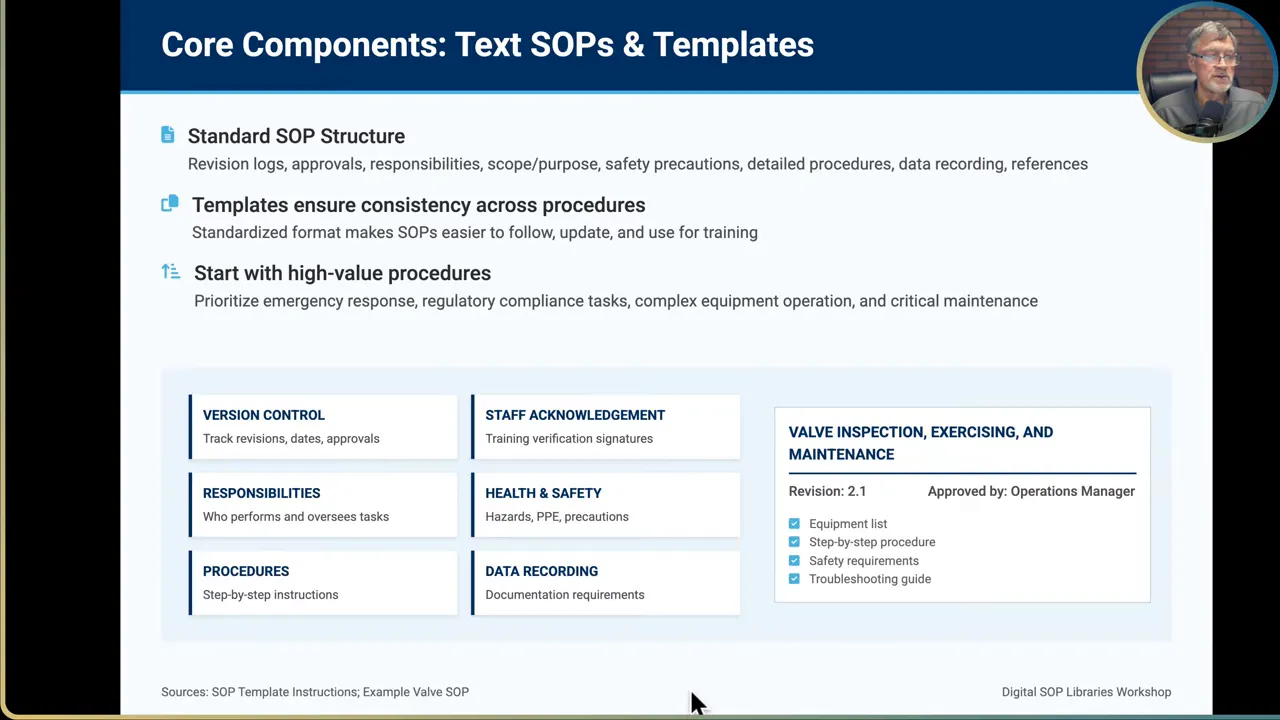

Step 3: Adopt a Standard SOP Template and Capture Knowledge

Consistency matters. A standardized template reduces friction when creating and reviewing SOPs and helps staff find the information they need quickly.

Essential elements of an SOP template

- Title Page Title, unique identifier, creation date, version number and utility logo

- Scope and Purpose Why this SOP exists and what it covers

- Definitions Acronyms and terms used in the SOP

- Roles and Responsibilities Who is responsible accountable consulted and informed for actions in the SOP

- Safety Precautions Hazards, required personal protective equipment and site setup details

- Equipment and Materials Lists parts, tools and consumables required

- Step by Step Procedure Numbered steps, decision points and troubleshooting guidance

- Data Recording What data must be captured, where and how

- References OEM manuals, regulations and related SOPs

- Revision Log and Acknowledgement Version history and area for staff signatures or electronic acknowledgement

Best practice for structuring the core steps

- Write procedures as clear simple numbered steps

- Include decision points with explicit instructions for yes and no outcomes

- Embed links to related manuals, diagrams and video segments

- Keep language direct and action oriented Use active voice and short paragraphs

Collecting knowledge from veteran operators

Schedule dedicated capture sessions with experienced staff. Use a guided interview to get step by step instructions then follow with an on site walkthrough and if possible a recorded demonstration. Ask operators to describe common failure modes, workarounds and troubleshooting sequences. Document not only the how but the why. That contextual detail is invaluable for new staff and auditors.

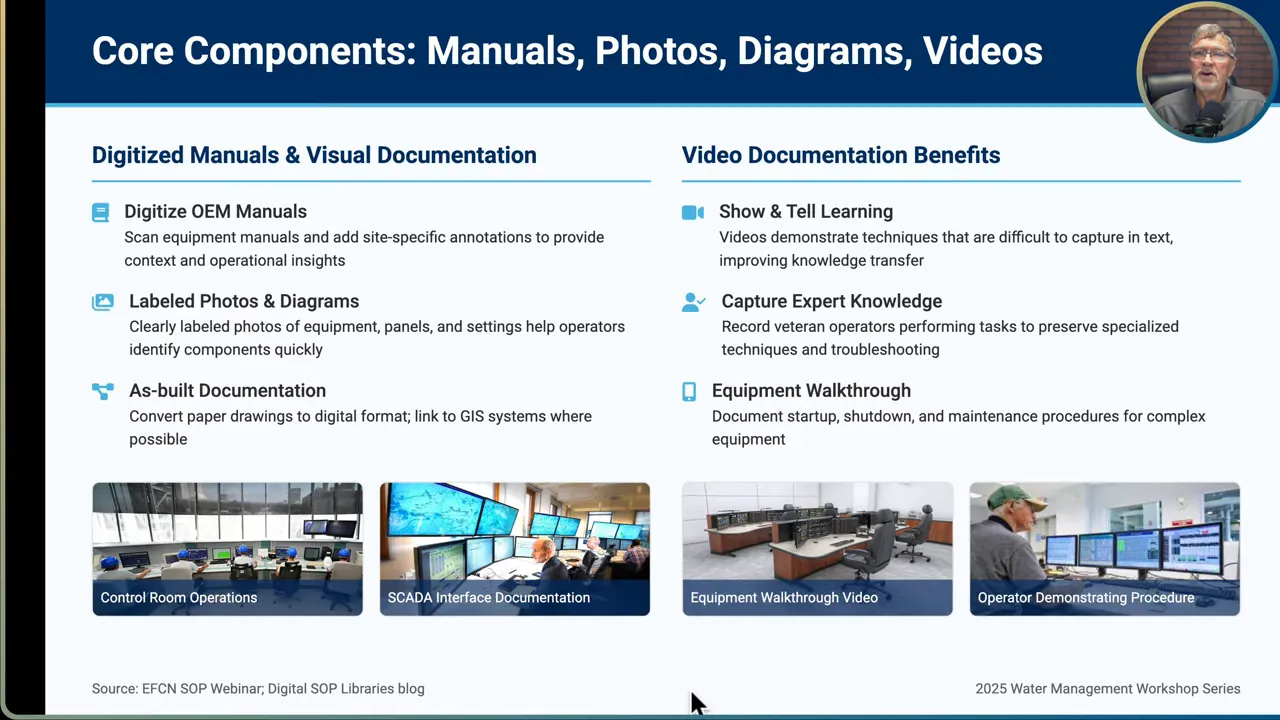

Step 4: Build Visuals and Video Content

Visual content turns abstract steps into clear practical guidance. Photos, diagrams and short video clips are the most effective. They are especially helpful for field technicians called to a task under time pressure.

Types of visual assets to include

- Digitized OEM Manuals Scan and annotate with site specific callouts

- Labeled Photos Components, valve tags, connection points and hazards

- Diagrams and As Built Drawings Convert paper drawings into digital format and link to GIS assets

- Micro Videos Two to five minute clips demonstrating individual steps

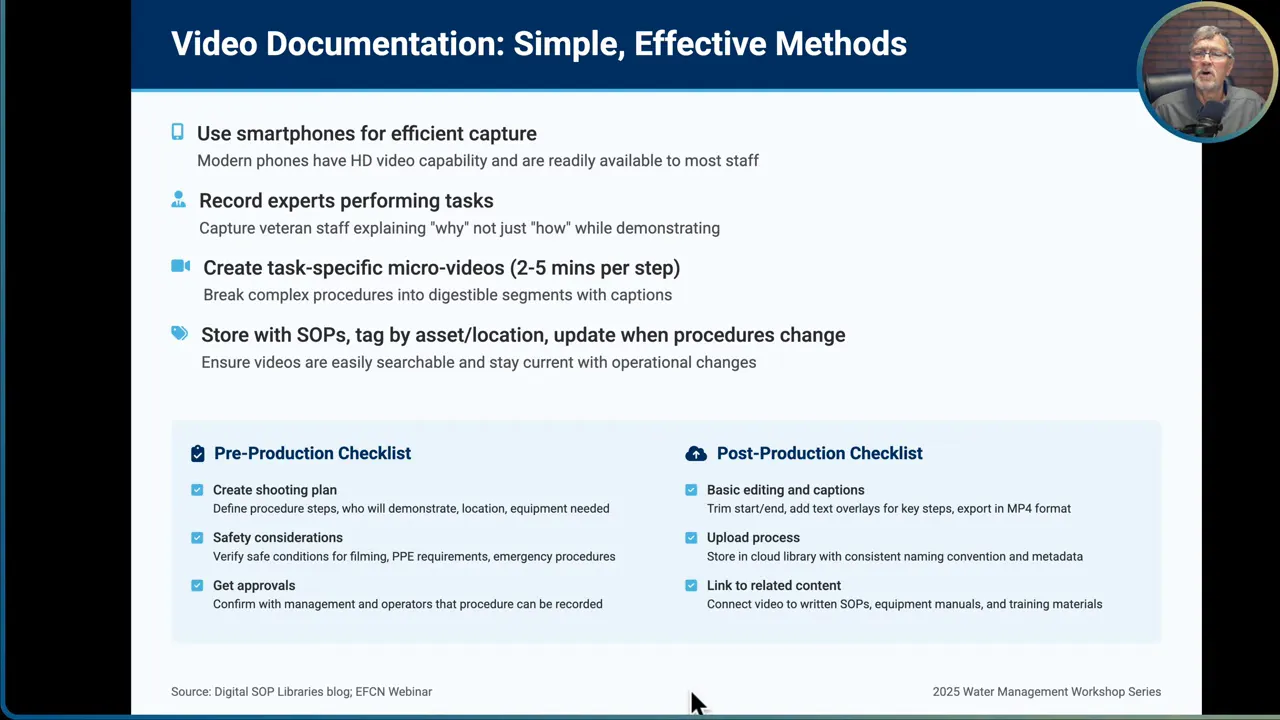

Practical video capture strategy

- Create a shooting plan that lists each SOP step and the video segment that will document it

- Record subject matter experts performing the task in real conditions

- Keep videos short task specific and captioned for quick scanning

- Use a smartphone for capture but plan the shots and narrate each action for clarity

- Store each clip with consistent file names and metadata that includes asset location coordinates

QR codes and on asset access

Consider placing QR codes on equipment that link directly to the relevant micro video and written SOP page. Scanning a code in the field brings up contextual guidance immediately. This is a powerful time saver and reduces confusion during emergencies.

Step 5: Run a Pilot Program Train Staff and Iterate

Launching a pilot with your prioritized SOPs validates the approach and builds staff buy in. A pilot should be time bound and focused on user feedback and real world use.

Pilot program steps

- Deploy the digital SOPs for three to five high value procedures

- Train operators and managers on how to access and acknowledge SOPs

- Collect usability feedback during normal shifts and incident responses

- Track version changes and usage analytics

- Iterate the SOPs based on feedback then re release updated versions

Training and acknowledgement

Require staff to acknowledge SOP review and maintain training logs. For regulatory procedures tie completion records back to compliance files. Include short micro learning sessions that use the videos and visuals to shorten onboarding time and reinforce correct behavior.

Step 6: Expand, Migrate and Integrate with Operational Systems

Once your pilot shows value, expand the library. The expansion phase moves beyond the initial high value SOPs to cover more assets and integrates the SOP library into other operational systems.

Expansion actions

- Migrate the next top 20 SOPs into the digital library

- Add photos diagrams and micro videos to each SOP

- Implement basic analytics and usage tracking to measure adoption

- Gather staff feedback and refine templates and metadata

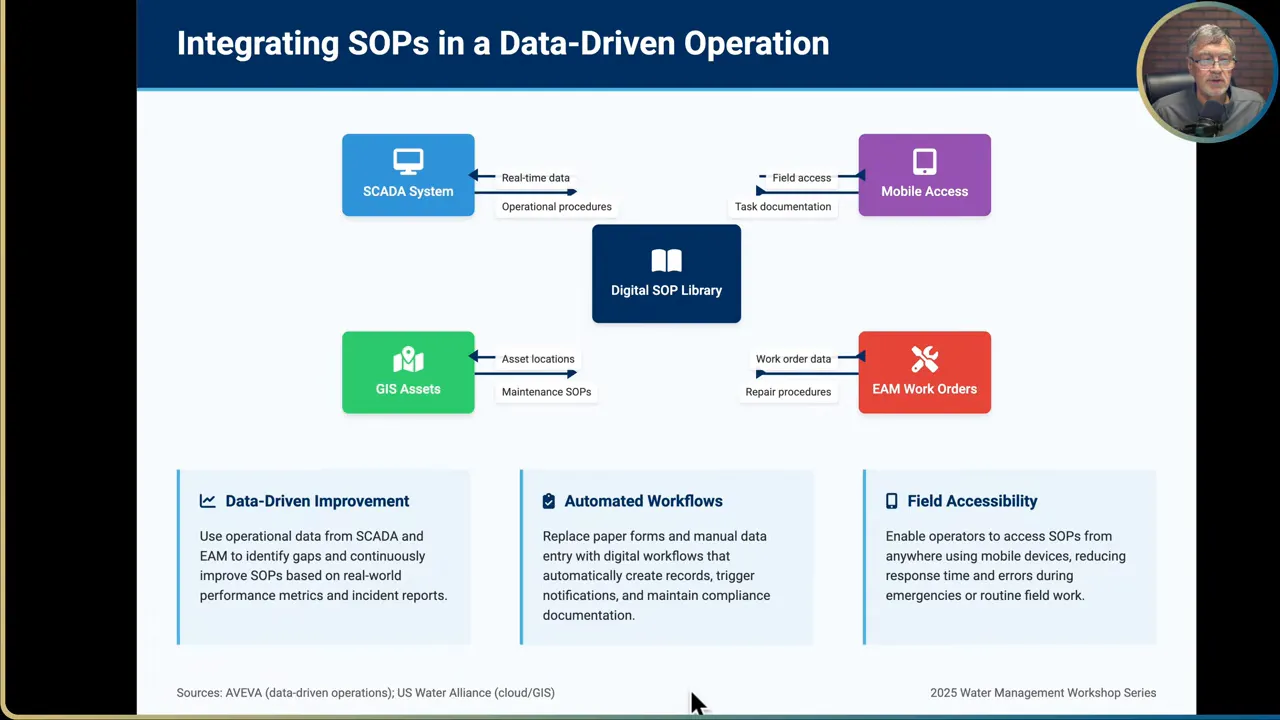

Integration with SCADA GIS and EAM

Digital SOPs become much more powerful when tied to operational data. Link SOPs to asset records in your GIS and to data streams from SCADA. As an example a tank level alarm from SCADA can open the SOP for pump station response and present the appropriate checklist and troubleshooting steps to the on duty operator. Work orders created in your enterprise asset management platform can reference the SOP by ID so technicians have all the required instructions and manuals attached to the work order.

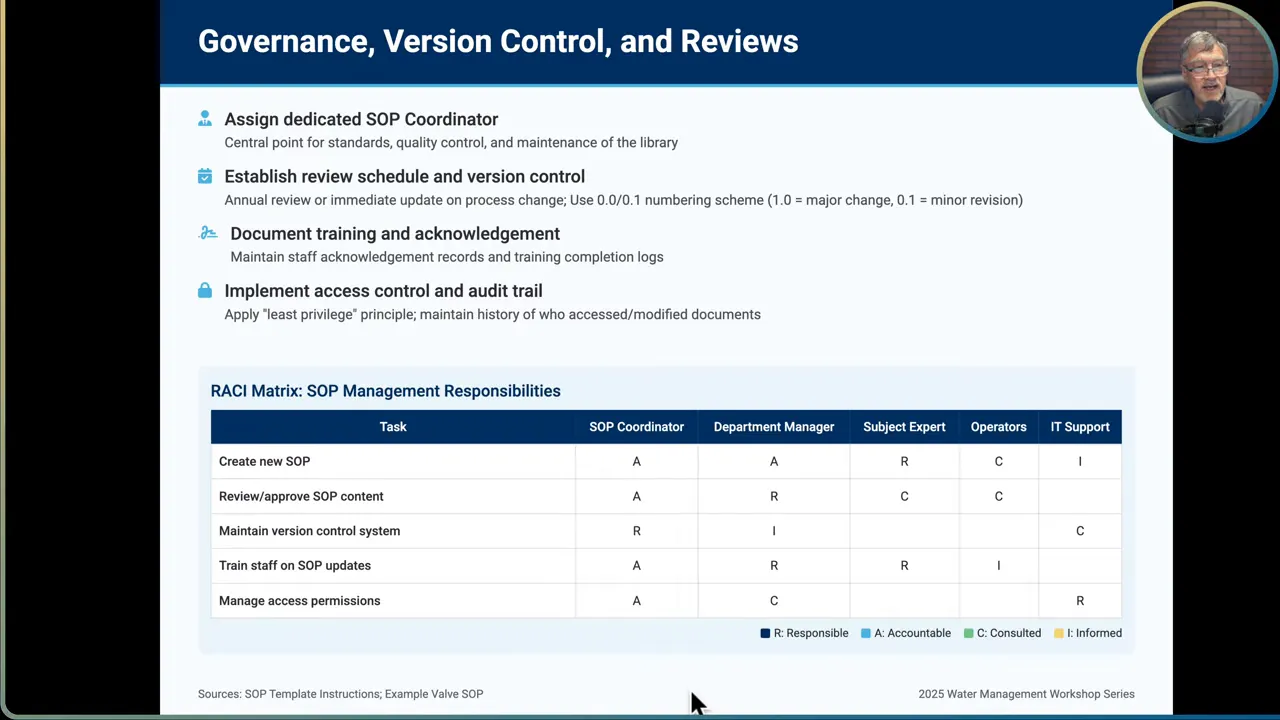

Step 7: Establish Governance, Version Control and RACI

Good governance prevents confusion and protects the library integrity. Assign roles and set review cadences before the library grows.

Governance actions

- Designate an SOP coordinator This person manages template quality version control and review schedules

- Implement a version numbering scheme Use major minor numbering such as 1.0 for major releases 1.1 for minor updates

- Set review cadences Annual reviews for most SOPs, more frequent reviews for safety critical procedures

- Maintain a revision log Include who made a change why and approval signatures

- Record training completion Keep logs of employee acknowledgements and training dates

RACI matrix

Use a RACI structure to clarify responsibilities for each SOP lifecycle task. Example roles include SOP coordinator department manager subject matter expert operators and IT support. Typical role assignments look like this

- Create new SOP accountable SOP coordinator responsible subject expert consulted operators informed IT

- Review and approve content responsible department manager consulted operators informed SOP coordinator

- Maintain version control responsible SOP coordinator informed department manager

- Train staff responsible department manager consulted SOP coordinator

- Manage access permissions responsible IT informed SOP coordinator

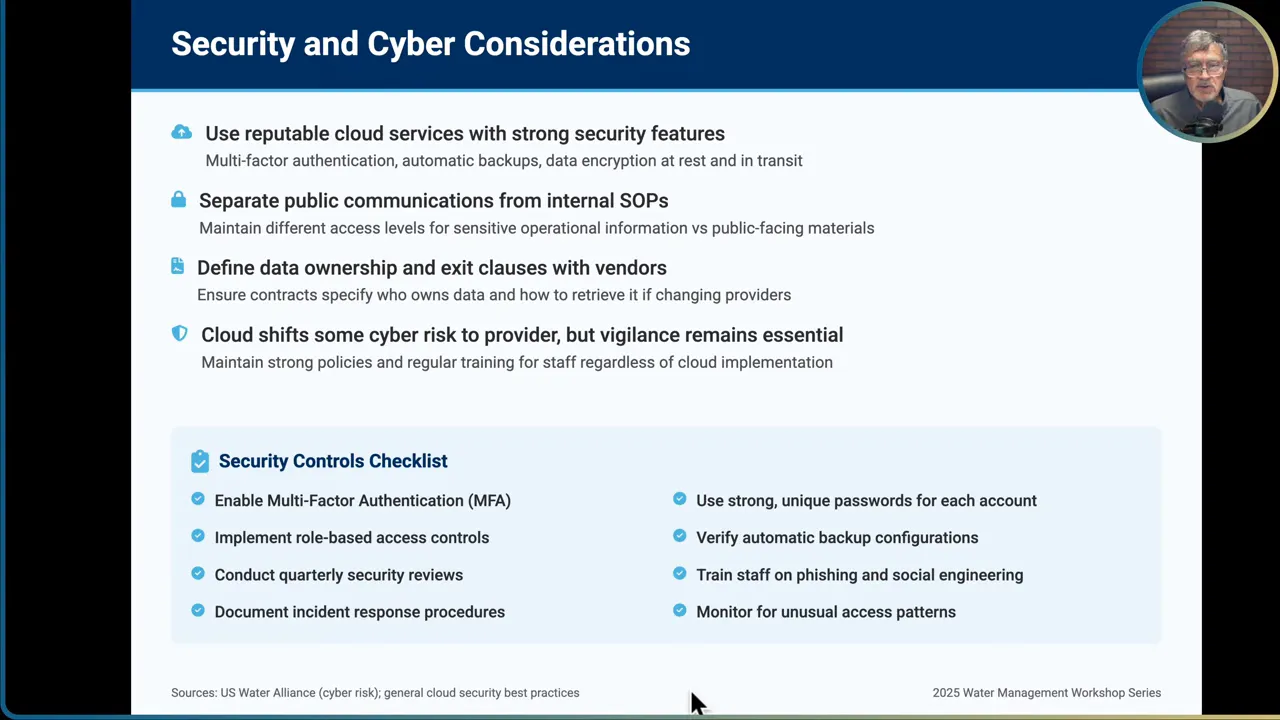

Step 8: Security and Cyber Considerations

As the system moves online protect the SOP library with appropriate security controls. Small utilities are increasingly targeted because operational technology can be an attack vector. Treat security as an essential part of the program not an optional add on.

Security checklist

- Use a reputable cloud provider with strong security features

- Enable multi factor authentication for all accounts

- Encrypt data at rest and in transit

- Separate public communications from internal SOPs use different systems or strict access controls

- Define data ownership and exit clauses when working with vendors

- Implement role based access control with least privilege principles

- Maintain audit logs and review them for unusual activity

- Verify backups are running and periodically test recovery

- Train staff regularly on phishing social engineering and proper credential use

Practical steps you can take today

- Enable multi factor authentication for your cloud platform

- Create role based accounts rather than sharing logins

- Schedule quarterly security reviews and a yearly tabletop incident response exercise

- Record access events and investigate logins from unexpected geographies

Step 9: Offline Access and Connectivity Planning

Rural water systems face limited connectivity. To make SOPs useful in the field plan for offline access and sync strategies.

Offline strategy options

- Allow selective folder offline sync to mobile devices so critical SOPs are available even without service

- Prioritize which SOPs need offline availability identify the mission critical ones first

- Use local device storage for videos and checklists that are required in low coverage zones

- Consider portable Wi Fi hotspots for crews working in long remote outages

Operational tips

- Pre stage relevant SOPs on technician devices when dispatching them to a remote job

- Use apps that automatically sync edits when the device re gains coverage

- Keep printed backups of truly critical safety procedures until offline reliability is proven

Step 10: Measuring Success and KPIs to Track

Define metrics to demonstrate value and guide continued investment in the program. Tracking usage and operational outcomes helps justify resources and shows improvement over time.

Suggested KPIs

- Staff onboarding time Measure the time from hire to independent operation on core tasks

- Number of SOP acknowledgements Percentage of staff who have reviewed and acknowledged assigned SOPs

- Usage frequency How often each SOP is accessed and which assets generate the most views

- Incident response time Time from alarm or issue alert to first appropriate action taken

- Operational incidents and errors Track number and severity of incidents attributable to procedural errors

- Audit findings Number and severity of regulatory findings over time

- Water loss or cost savings In systems with SCADA integration track reductions in loss or overtime

How to collect the data

Use analytics from your cloud platform SCADA and any EAM or work order system. For example build simple dashboards using Google Sheets or Google Data Studio that combine SOP access logs with alarm events from SCADA. That allows you to calculate things like average time between an alarm and SOP access.

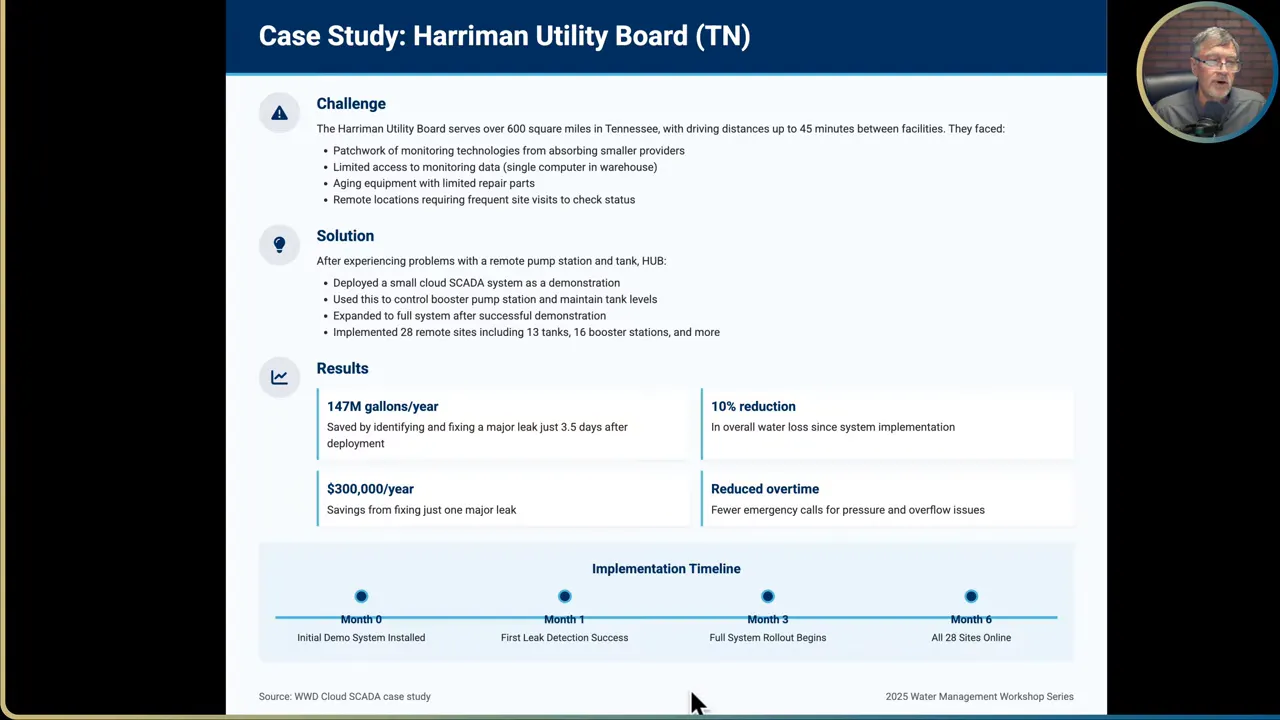

Step 11: Example Case Study Harriman Utility Board

An illustrative example shows how a focused digital transition delivered quick value. A rural utility serving a large geographic area with long drives between facilities experienced limited monitoring and a patchwork of technologies. They deployed a pilot cloud SCADA system to monitor and control a booster pump station and tank levels. This was a demonstration project and training opportunity for staff.

Rapid outcomes from a small pilot

- Within three and a half days a major leak was found and repaired saving an estimated 147 million gallons a year

- This reduction represented roughly 10 percent of overall water loss and about 300000 dollars in annual savings

- They reduced emergency calls and overtime by having real time monitoring and digital SOPs tied to alarm responses

- In six months they expanded the solution to 28 remote sites demonstrating how a pilot can scale

Lessons from the case study

- Start with a narrow pilot and focus on a measurable outcome

- Leverage SCADA data to identify problems quickly

- Digitize procedures tied to alarm response to shorten time to resolution

- Use the pilot to build momentum for a broader rollout

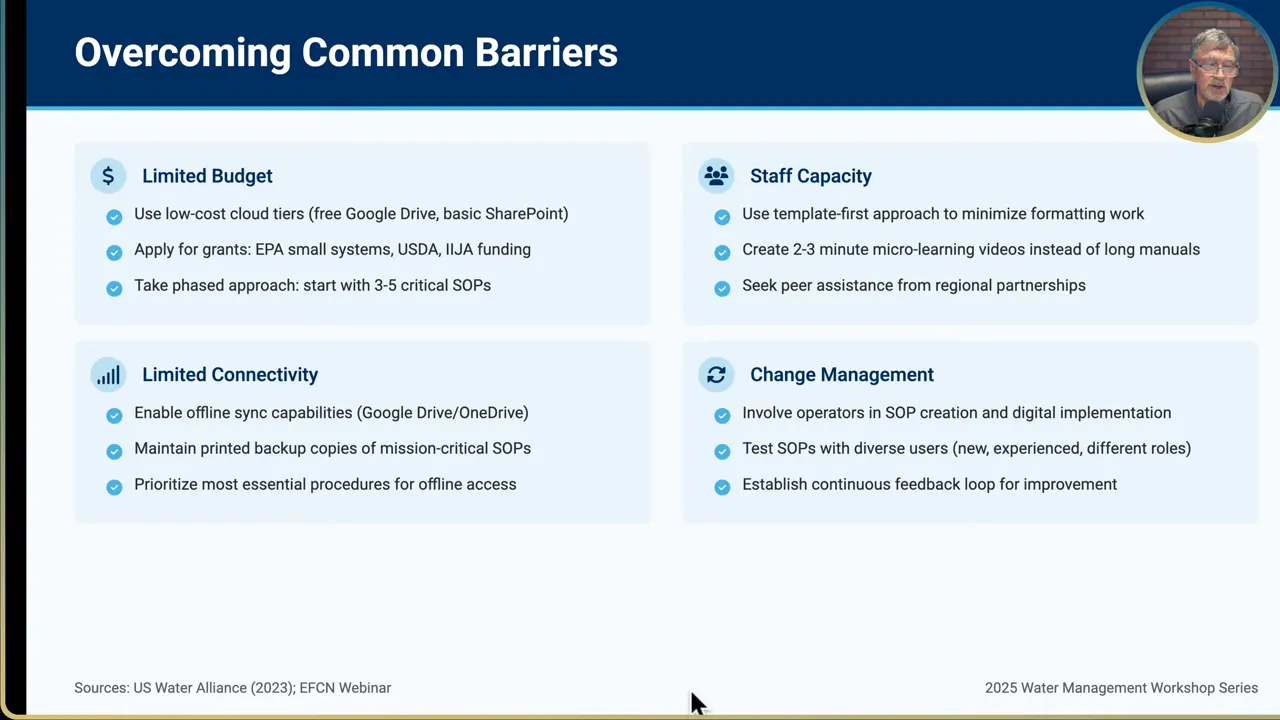

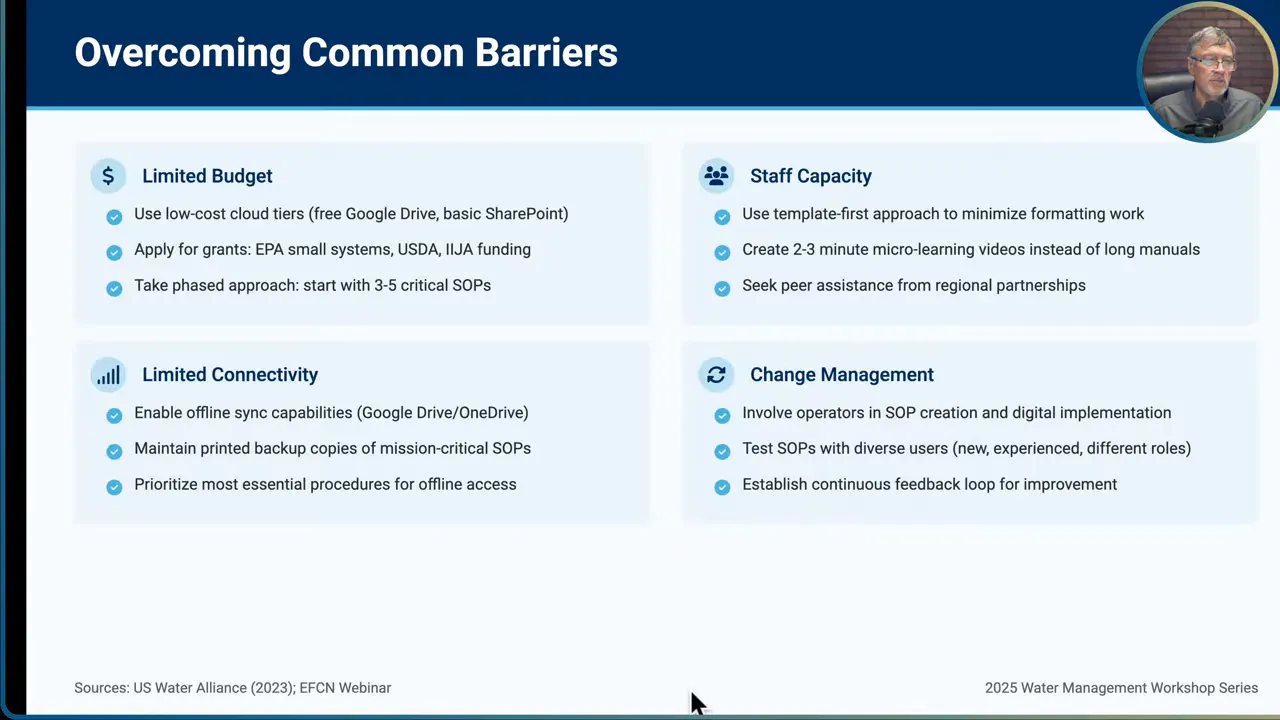

Step 12: Overcoming Common Barriers

Small water utilities face budget constraints staff capacity limits and intermittent connectivity. Each barrier can be managed with practical strategies.

Budget constraints

- Use low cost cloud tiers such as the free Google Drive or basic Microsoft 365 plans during the pilot

- Apply for grants through EPA Small Systems programs USDA and other funding sources for digital upgrades

- Phase spending over time migrate incrementally rather than purchase large enterprise systems up front

Staff capacity and skills

- Use a template first approach to lower the time required to create SOPs

- Create short micro learning videos instead of expecting staff to read long manuals

- Identify staff champions who will own parts of the program and provide peer training

- Seek regional peer assistance from other utilities or technical assistance organizations

Connectivity

- Enable offline sync and pre stage critical SOPs on mobile devices

- Maintain printed backups for mission critical procedures until digital reliability is proven

- Prioritize the essential SOPs that must be available in low connectivity areas

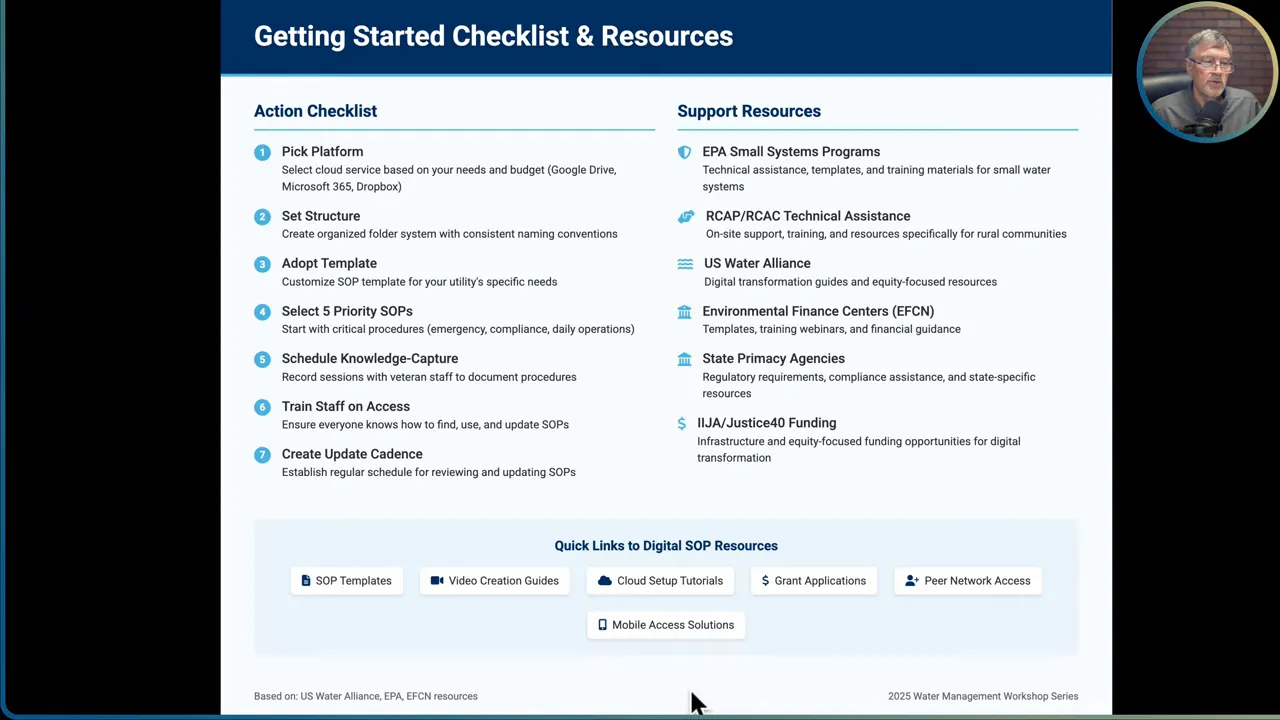

Step 13: Getting Started Checklist

Use this checklist as your immediate action plan for the first 90 days. It condenses the steps you need to take to build momentum and deliver early wins.

- Select a cloud platform and create accounts for key staff

- Establish folder structure naming conventions and metadata schema

- Adopt a standard SOP template and version numbering system

- Identify and select three to five priority SOPs for the pilot

- Schedule knowledge capture sessions with veteran staff and record demonstrations

- Create micro videos and label photos for the pilot SOPs

- Deploy the pilot SOPs and train staff on how to access and acknowledge them

- Collect user feedback track usage and iterate on the SOPs

- Document the governance RACI assign an SOP coordinator and set review cadence

- Enable security controls for cloud accounts and turn on multi factor authentication

Step 14: Support Resources and Where to Find Help

Do not try to do everything alone. There are many organizations and local networks that provide assistance tailored to small water systems.

Potential support partners

- EPA Small Systems Programs

- Regional Capacity Assistance Programs RCAP and RCAC

- State Rural Water Associations and State Primacy Agencies

- Environmental Finance Centers and US Water Alliance resources

- Technical service providers that offer video documentation and QR code linking

When to call in outside help

- When you need professional video production and QR code asset linking for a large asset list

- If you require complex SCADA integration with automated workflows and EAM systems

- When applying for grants or financing to scale a broader digital transformation

Step 15: Continuous Improvement and Long Term Roadmap

Digital SOP libraries are not a one time project. Plan for continuous improvement and a roadmap that scales from pilot to enterprise capability.

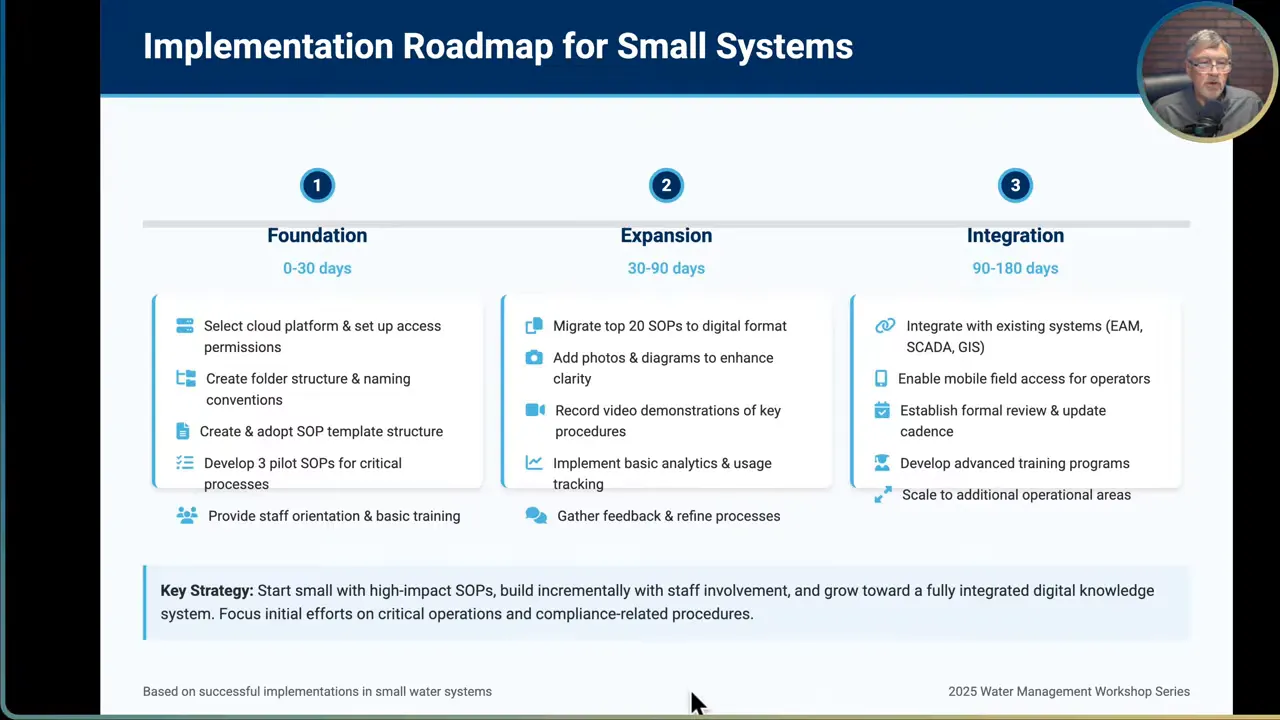

Three phase roadmap overview

- Foundation 0 to 30 days Select platform adopt templates create folder structure and develop 3 to 5 pilot SOPs

- Expansion 30 to 90 days Migrate top 20 SOPs add photos diagrams and videos implement analytics and gather feedback

- Integration 90 to 180 days Integrate with SCADA GIS and EAM enable mobile field access and establish regular review cadence

Iterative improvement model

- Capture knowledge implement SOPs

- Measure usage and operational outcomes

- Refine SOPs based on real world incidents and staff feedback

- Automate workflows over time and tie SOPs to alarms and work orders

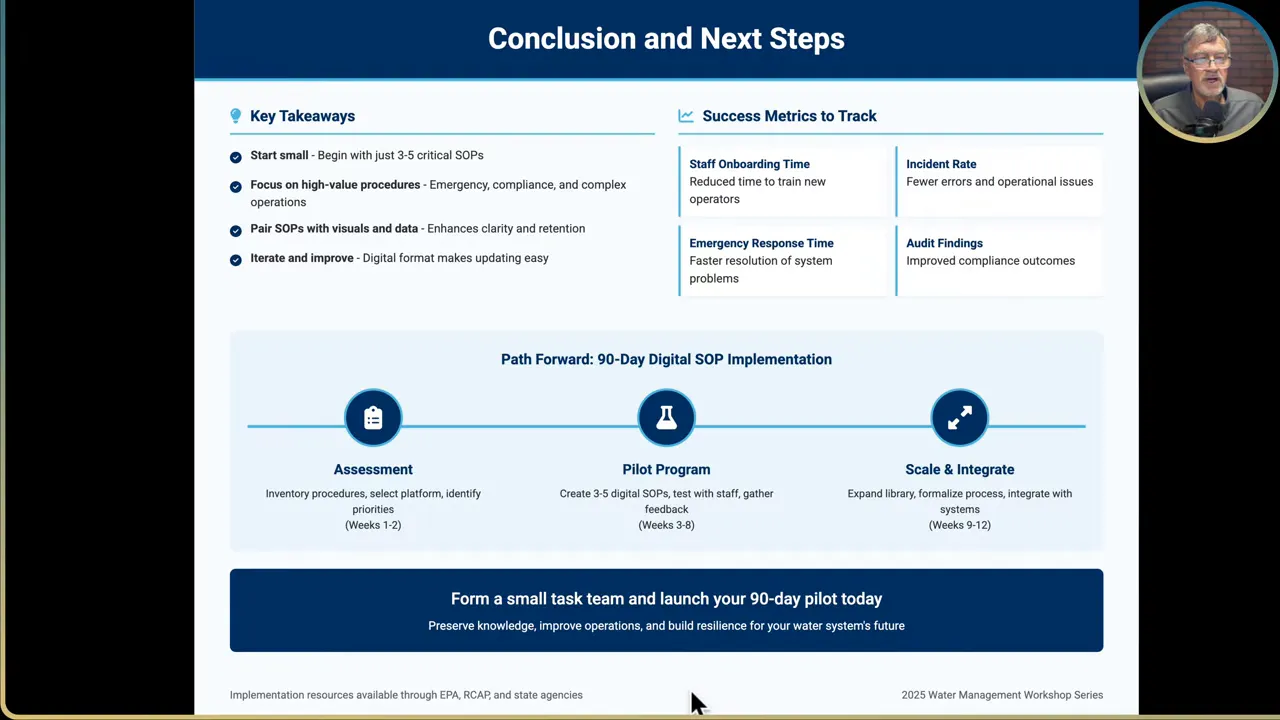

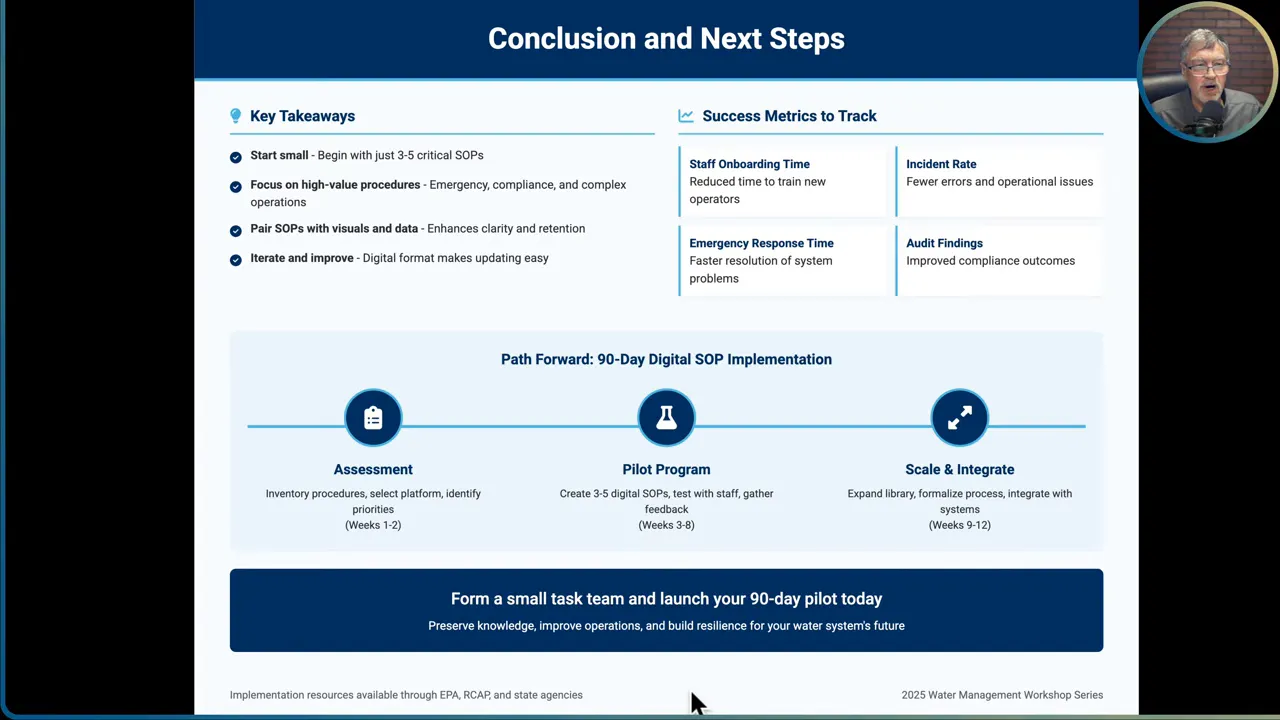

Conclusion and Next Steps

The path from paper to a data driven organization begins with practical steps that preserve knowledge improve safety and deliver measurable benefits. Build a digital SOP library starting with three to five mission critical procedures. Use a consistent template add photos diagrams and short videos link SOPs to assets in GIS and eventually integrate with SCADA and EAM systems. Prioritize governance security and offline availability and measure success with concrete KPIs.

Remember these key points

- Start small A focused pilot wins staff trust and yields quick measurable value

- Capture institutional knowledge Digitize the expertise of veteran operators before it leaves

- Pair text with visuals and video Micro videos and labeled photos reduce ambiguity in the field

- Govern and secure Assign an SOP coordinator and protect data with MFA and role based access

- Iterate Use data from SCADA and usage analytics to continuously improve procedures

Take the first step today. Pick a cloud platform, adopt a template schedule knowledge capture with an experienced operator and publish your first SOP. That initial investment delivers immediate operational clarity helps protect your system from knowledge loss and sets the stage for a broader data driven transformation.

If you follow the steps in this guide you will move from paper chaos to a reliable searchable digital library that reduces risk improves onboarding speeds and ultimately protects the health of the system and the community it serves.