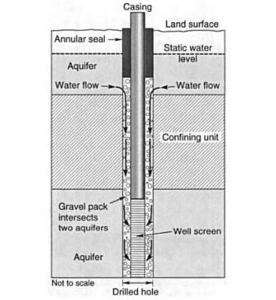

The well seal, also known as a sanitary seal, is an important component of a water well that protects the well from surface water contamination and provides protection for the upper part of the well. The seal consists of a mixture of cement, bentonite and sand that is placed to make a water tight seal in the annular space between the casing and the borehole wall.

Most state well regulations contain a requirement for a minimum annular seal depth. These regulations usually contain requirements for a minimum seal depth for different classes of wells. In California, for instance, a public water supply (PWS) system well is required to have a minimum seal depth of 50 feet while in Tennessee, requirements include a minimum of 19 feet of casing and 10 feet of seal.

Minimum seal depths specified in the regulations are just that – a minimum depth. It is important to take the geology of the borehole into consideration when determining the actual depth of the seal. Fractures in bedrock and wells screened across multiple aquifers can result in an inadequate seal, even if it meets regulatory requirements

We find that many water quality issues impacting PWS wells often have a surface water component – especially in cases of nitrates and E. coli. Often the surface water intrusion can be traced to an inadequate seal that, while it meets the minimum regulatory standards, does not seal the well against surface water intrusion based on a number of geologic factors. For instance, we were consulted on an E. Coli contamination issue in several PWS wells in a volcanic bedrock and, after examining the well logs, determined the 50 foot seals to be inadequate due to shallow lost circulation zones encountered during drilling that we not adequately sealed off. This allowed intrusion of surface water containing E. coli from surrounding properties with septic/leach field systems. In another case of nitrates impacted a well drilled into a fractured granite, a review of the well logs again revealed a seal that met minimum regulatory requirements did not address shallow fracture zones that extended to 70 feet below the ground surface and allowed intrusion of nitrate impacted surface water into the well. In either of these cases, an adequate seal could have been installed based on geologic information available at the time of drilling, but a decision was made to not use the available information and just to install the minimally acceptable seal according the regulations.

An inadequate seal resulting in impacts to well water quality can be very expensive in terms of required treatment of the impacted water or drilling of a new, properly constructed well. Our philosophy is that it is best to construct the well properly in the first place and that usually means have both an adequate geologic log of the borehole and a geophysical log, as well.

How can i seal between two aquifers, like the top has salty water and the below one has fresh water, i want to seal the top one not drain the lower one

Thanks

If it is in a new well, it is relatively easy to design the well to seal off the poor water quality zone by using blank casing and extending the annular seal into a clay or relatively impervious zone below the poor water quality zone to make an effective seal so that no poor quality water can migrate into the well. The trick is to do water quality testing during well drilling so that you know where the zones of poor water quality are and then design the well accordingly.

It becomes a bit trickier if you have an existing well with a zone of poor quality water. In that case, we typically recommend a well modification process that uses packers to isolate the zone to be sealed off and then pressure grouting through the screen to seal off the section of poor quality water. You can finish by using a swage tool to install a patch inside the well to stabilize the zone that has been sealed. If done properly, that should sufficiently isolate the zone to stop any poor quality water from entering the well.